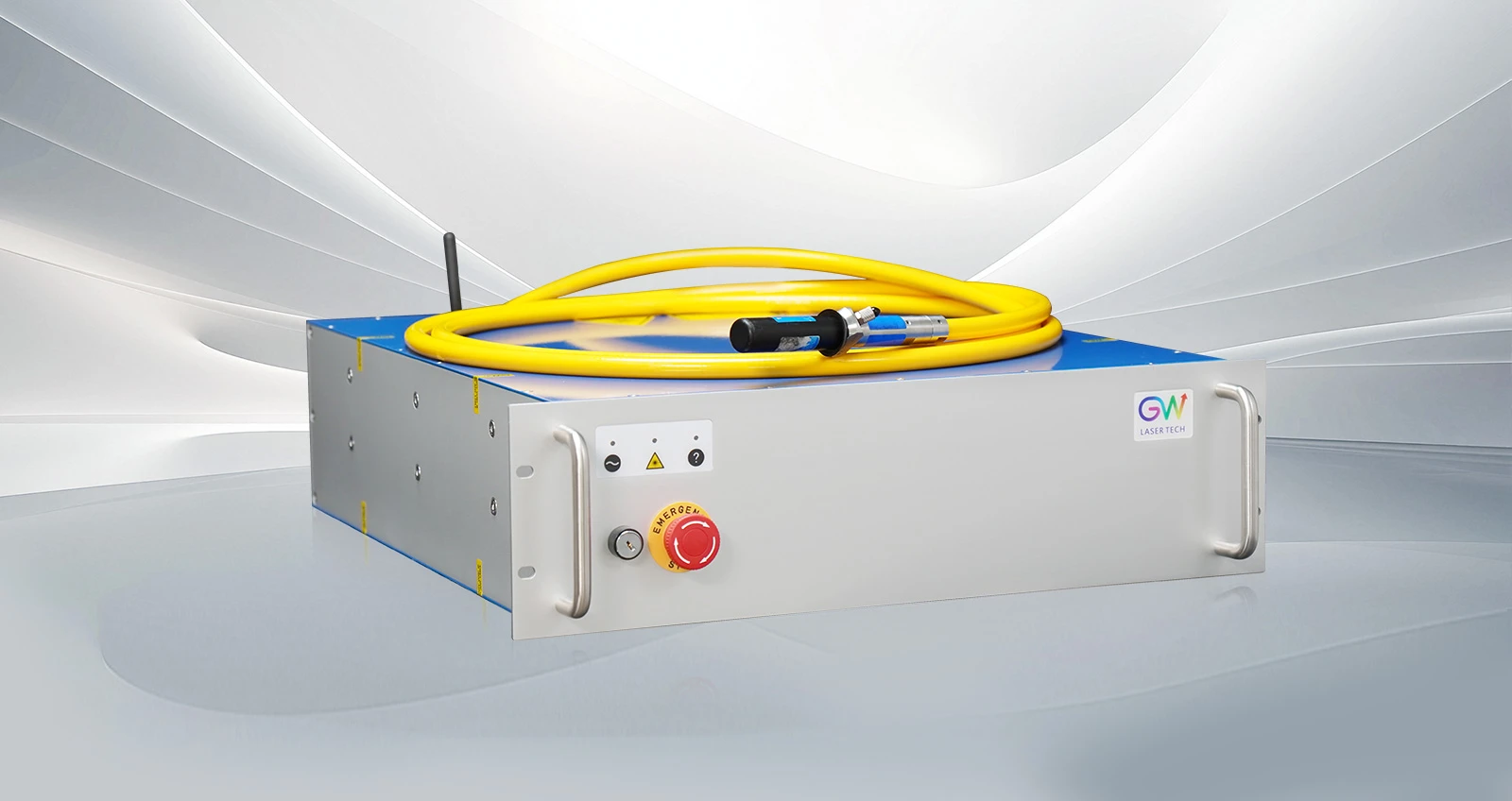

Quasi-Continuous (QCW) Fiber Laser

The Quasi-Continuous (QCW) Fiber Laser combines some characteristics of both continuous wave and pulsed fiber lasers. It retains many advantages of the continuous fiber laser while also possessing some unique features and benefits.

Peak Power

Peak Power 0.01-50 ms Pulse Duration

0.01-50 ms Pulse Duration Maximum Pulse Energy

Maximum Pulse Energy Higher Cost-Effectiveness

Higher Cost-Effectiveness

High Peak Power and Single Pulse Energy

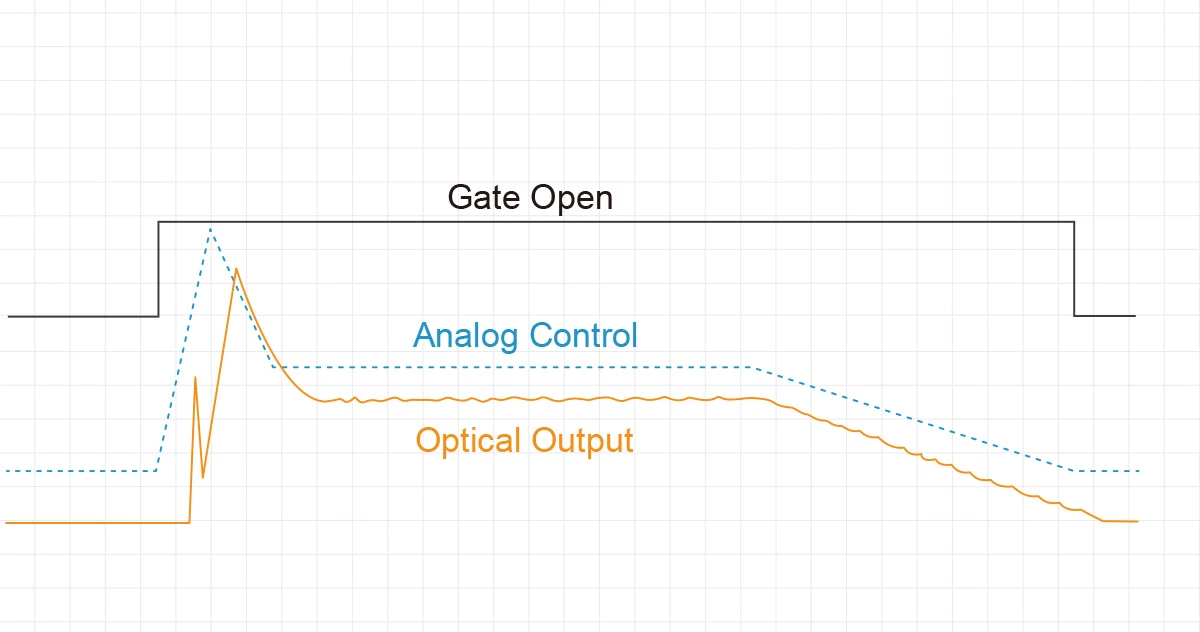

The QCW Quasi-Continuous Fiber Laser achieves high peak power output similar to that of a pulsed laser by specially designing and controlling the operating mode of the continuous fiber laser, while maintaining a certain level of average power to meet different application requirements. It can switch between continuous mode and pulsed mode, and in the pulsed mode, it achieves higher peak power at lower average power by limiting the laser duty cycle.

Application Advantages

High Energy Density and Strong Penetration

Under the same average power, the QCW Quasi-Continuous Fiber Laser can achieve greater peak power than the continuous fiber laser, resulting in higher power density. In material processing, such as welding of copper and aluminum alloy sheets, it can produce deeper penetration and better results.Low Thermal Impact

Unlike continuous lasers that continuously act on materials, the QCW laser intermittently acts on materials, resulting in a smaller heat-affected zone and lower thermal input.Flexible Modes

Can be set to pulsed mode or continuous mode, allowing for better adaptation to different processing needs. In pulsed mode, it can also minimize thermal impact on the component during cutting.

Application Cases

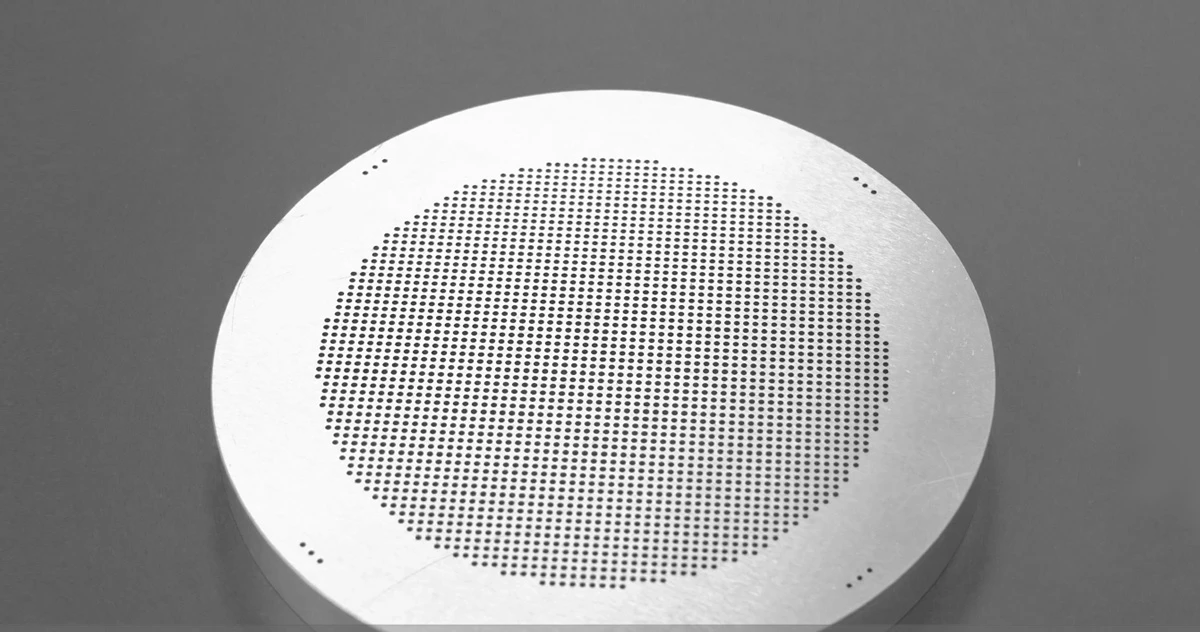

- Micro-hole Processing

- Precision Welding

- Ceramic Cutting

Screen

No Data

No data

Leave Your Message

We will reply you via email in 24 hours(Except holidays)

0

0