Temperatures are plummeting, the cold wave is coming, people need to add clothes, lasers should also pay attention to frost protection. In order to avoid laser damage caused by freezing in the cold winter, GW Laser has prepared a guide to prevent freezing, to ensure that every laser can be safe through the winter.

How to prevent freezing?

1. The ambient temperature for normal operation of the laser is in the range of 5~45℃, and the optimal working temperature is about 25±3℃. If necessary, you can add the necessary heating equipment to ensure that the temperature around the laser is above 5℃;

2. add antifreeze in time to avoid freezing the cooling water in the cooling tube and lead to cooling tube rupture. GW Laser suggests that when the temperature is lower than 0 ℃, you need to change the cooling water to antifreeze in time;

3. When the power is off for a long time, the cooling water in the equipment should be completely drained and the equipment should be stored in the environment above 5℃.

How to drain the equipment?

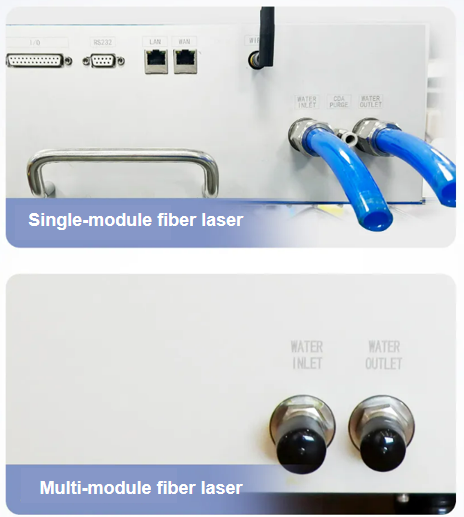

1. Cut off the laser and cooling system power supply, open the sewage valve

2. Disassemble the water inlet and outlet water pipe;

3. Open the chiller filter core, drain the filter core of water;

4. Recommended to use 0.2MPA (2KG) gas to the water inlet pipe end, drain the laser water

Note: equipment drainage gas should be accessed from the inlet port, can not be blown from the outlet, the pressure of the drainage gas should not be too large, otherwise The pressure of the drainage gas should not be too high, otherwise the laser may be damaged.

How to choose antifreeze?

Pay attention to the period of use, regular replacement of antifreeze, cleaning of pipelines, replacement of deionized water;

Different brands and varieties of antifreeze chemical composition may not be the same, after mixing may be a chemical reaction, the loss of antifreeze effect as well as the reaction of the contamination of the residue, so it is not recommended to mix it.

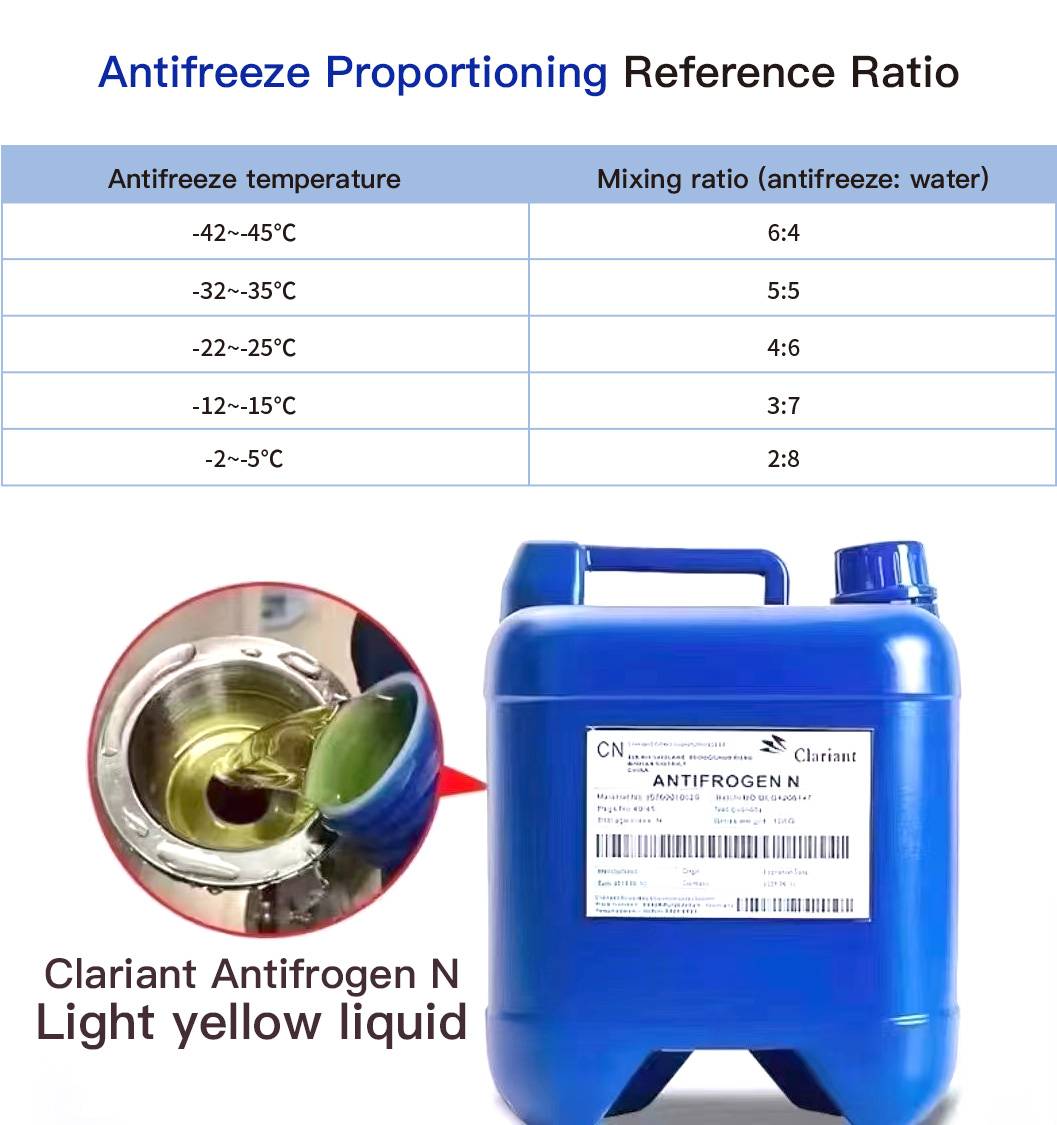

Antifreeze brands and ratios are recommended to recommend the selection of the CLARIANT (CLARIANT) brand of Antifrogen-N ethylene glycol - water type antifreeze.

Antifreeze ratio can be selected according to the ambient temperature, specific reference:

Attention is needed to power on the machine in winter

Ensure that the indoor temperature of 5-35 ℃, the laser equipment can be turned on to use;

Check whether the water-cooled tube icing, icing laser equipment can not be turned on;

If there is ice, please open the air conditioning or heating facilities, the laser equipment in the ambient temperature of 5-35 ℃, and static for more than 4 hours, to be naturally melted icing to carry out the next step of the operation, do not take violent de-icing, so as not to damage the hardware of the equipment. Damage to equipment hardware;

Confirmation of laser equipment without ice, you need to turn on the chiller for preheating;

To be the chiller cycle temperature rises to the normal temperature (recommended temperature: 25 ± 3 ℃ or so), before you can turn on the laser;

Normal power on, the energy will be adjusted to 30% or less, empty light warm-up of about 10 minutes, and then carry out normal production operations.

Although the ice and snow are cold, the enthusiasm is always there! If you encounter any problems, please feel free to call the national free service hotline 400-0111-976, we will be the first time for your service, GW light Huizhou laser to accompany you warm through the winter.

0

0