As the global laser market rapidly evolves, GW Laser seizes the era of import substitution opportunities, leveraging laser processing technology as new quality productive forces. We actively drive technological innovation, diversified applications, global market expansion, and smart services to empower global industrial technological upgrades.

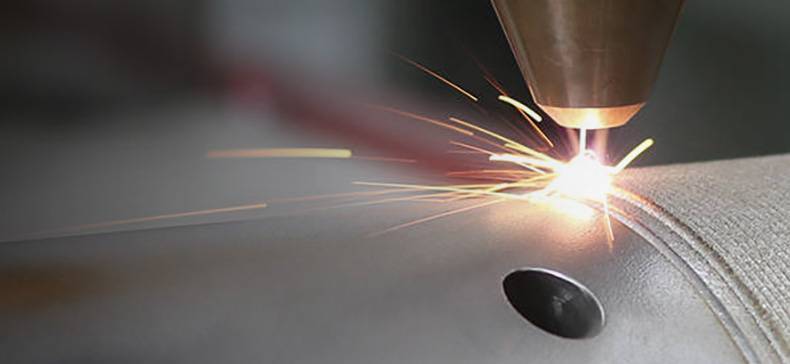

Laser cladding technology, an advanced surface treatment method in laser processing, has been widely adopted across industries to address challenges beyond traditional repair techniques.

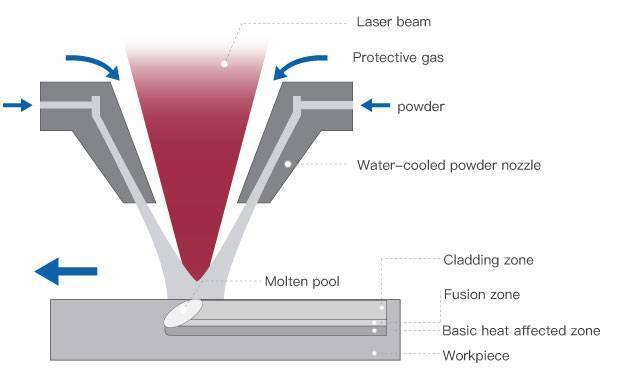

The laser cladding process involves depositing selected coating materials onto substrate surfaces through various feeding methods. Under laser irradiation, both the coating material and a thin substrate layer melt simultaneously, then rapidly solidify to form a surface coating with minimal dilution and metallurgical bonding to the base material. This significantly enhances surface properties including wear resistance, corrosion resistance, heat tolerance, oxidation resistance, and electrical characteristics. The technology finds extensive applications in surface modification, repair & remanufacturing, and rapid prototyping.

Laser cladding technology has the advantages of automatic repair, metallurgical combination of repair layer and matrix, high strength, small heat injection, small part deformation, precise and controllable repair size, etc. It is non-polluting to the environment and greatly improves the performance of repair. Laser cladding technology requires high performance of the laser, it is crucial to choose a high-performance, stable and reliable laser.

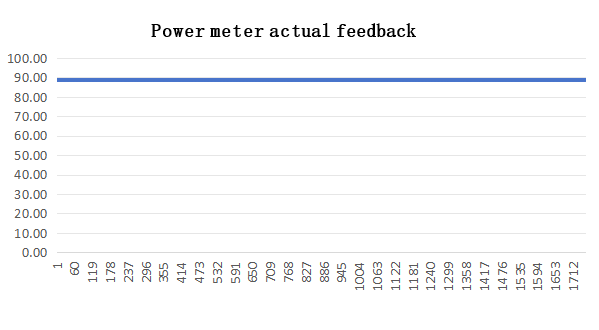

Continuously adjustable output power from 1% to 100%.

Different from the market cladding lasers whose output power is adjustable from 10% to 100%, GW laser cladding lasers support continuously adjustable output power from 1% to 100%, which can meet the needs of different processes, and can perfectly realize both rough processing and fine cladding, ensuring the accuracy and stability of the cladding process.

Take GW laser cladding laser YLLS-Clad-6000-W as an example, it can produce light within the power range of 60-6000W, and the lowest 100W can produce light stably, so it can be used for both low power and high power.

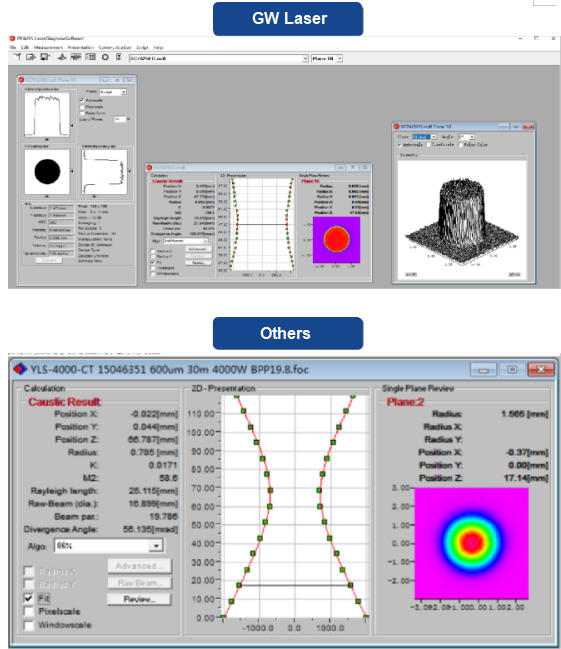

Single-mode, dual-cavity design.

Spot uniformity equivalent to multimode lasers

GW laser cladding laser adopts single-mode dual-cavity design with spot uniformity equivalent to multi-mode lasers, and its flat-top light output can effectively improve the uniformity and stability of the laser beam, ensure the cladding area is uniformly heated, avoid material loss and process defects due to uneven spot, and the edge of the cladding material will not be hairy.

The larger the BPP, the more uniform the beam distribution.

GW cladding laser:

BPP<50mm-mrad@800μm.

BPP<35mm-mrad@600μm.

Friendly:

BPP<20mm-mrad@600μm.

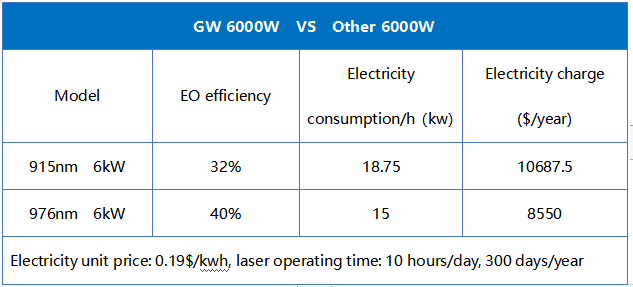

Save more than $2000/year

GW laser cladding laser adopts 976nm high-efficiency bi-directional pumping technology, electro-optical conversion efficiency ≥40%. GW Laser YLLS-Clad-6000-W laser, operating in the same environment, can realize a comprehensive annual savings of more than $2000.

Jiangsu Everest Laser Technology Co., Ltd. is a national high-tech enterprise focusing on laser processing head and laser on-site processing, equipped with GW Guanghui laser 6000W cladding laser, used to find that not only the machine is inexpensive, covers a small area, and the performance is particularly stable, and the use of special power saving, a machine can save at least 10,000 yuan a year!

In the process of laser cladding, it is crucial to choose a high-performance, stable and reliable laser. GW Laser cladding lasers have been highly recognized by customers in a number of industries due to their high efficiency, high stability, high quality spot uniformity and other advantages. In the future, GW laser cladding lasers will play an important role in more fields together with our customers, providing more efficient and economical solutions for equipment maintenance and surface enhancement in various industries.

The price of GW laser cladding lasers has been reduced by 40%, and the market-proven mature technology combined with the rock-bottom price has triggered a lot of customers to grab orders! Call 400-0111-976 toll-free hotline to get the exclusive industry solutions + limited time great benefits quotation, this wave of dividends you can not miss!

0

0