Copper and aluminum, prized for their unmatched conductivity and ductility, dominate cutting-edge industries like electric vehicles (EVs), 3C electronics, and aerospace. Yet their Achilles’ heel – 90%+ laser reflectivity – has long plagued manufacturers:

EV Battery Trays: Unstable welds risk thermal runaway

Copper Circuit Boards: Micro-splattering compromises signal integrity

Aerospace Components: Inconsistent cuts increase part rejection rates

Traditional lasers struggle with two fatal flaws:

1. Slow Processing: <30% laser absorption → 2-3x longer cycle times

2. System Damage: Back-reflected light fries $50k+ laser modules

3000W 14μm High-Brightness Laser – Piercing the Reflection Barrier

When the power of the laser is constant, the smaller the core diameter, the greater the power density. Therefore, the brightness of the laser is of vital importance. The higher the brightness, the stronger the equipment's ability to resist high reflectivity. By using a high-power-density laser beam, key holes can be quickly drilled on the material surface, increasing the material's absorption rate of laser, and achieving efficient and rapid processing of high reflectivity materials.

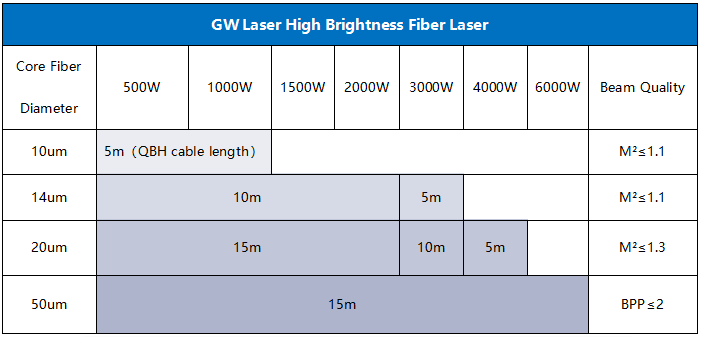

GW Laser's current high-brightness fiber lasers feature high power density and excellent beam quality. A 1000W core can achieve a thickness of 10μm, and a 3000W core can reach 14μm. They can easily complete the cutting and welding of high-reflective materials such as red copper, brass, and aluminum. At the same time, they can complete processing tasks at a faster speed, improve production efficiency, and reduce production costs. Especially in large-scale industrial production, it can significantly shorten the processing time and improve economic benefits.

ABR Technology

When processing highly reflective materials, if excessive return laser enters the interior of the laser, it will pose a risk of damage to the laser. To avoid the above problems, GW fiber lasers adopt the "ABR Super Strong Anti-High Reflection Technology", which stripping the backlight in three layers to reduce the damage of the backlight to the laser resonant cavity and effectively increase the stability and reliability of the laser.

A backlight detection and stripping device is added to the output head to detect the backlight in the first place and perform stripping. Before entering the beam combinator, a two-stage backlight detection and stripping device was added. The backlight was stripped step by step in stages to ensure that the backlight did not enter the interior. There is also a secondary backlight detection and stripping device in front of the red light to protect the red light indicator from damage.

Activating Next-Gen Productivity: GW Empowered NEV Manufacturing

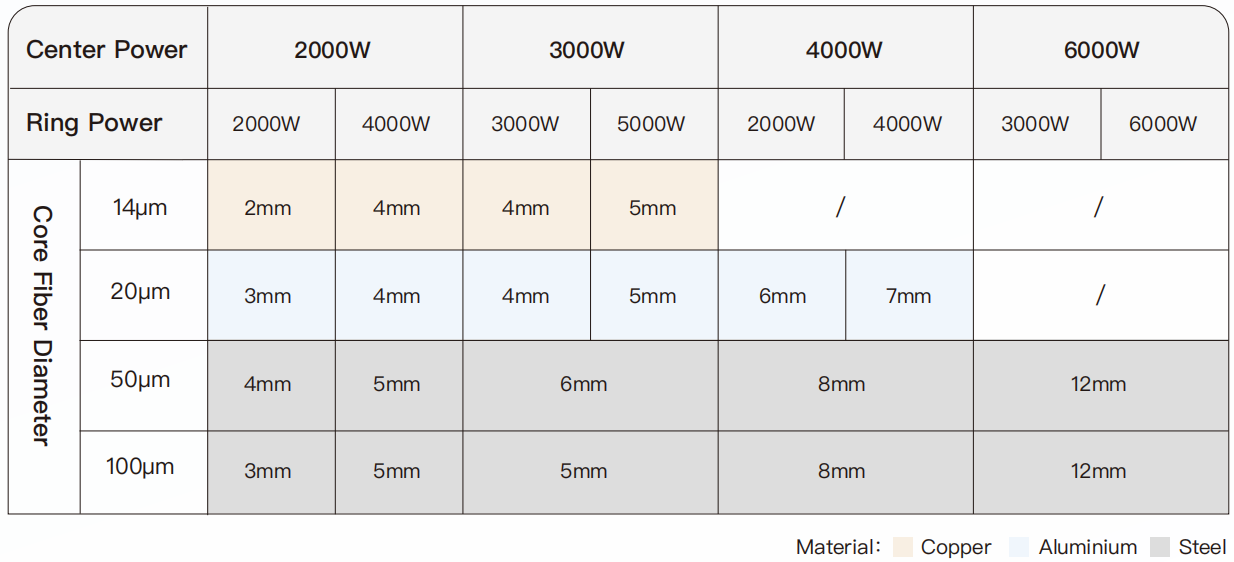

With its profound accumulation in the field of high-brightness fiber lasers, GW Laser has specially developed the FRM tunable beam fiber laser. The power of the two laser beams can be independently adjusted, and the power switching is at the microsecond level, bringing greater potential to the laser welding process.

FRM tunable beam fiber lasers can achieve a welding process without pores, cracks, and extremely low spatter in the production and processing of new energy vehicles that extensively use copper materials. The weld formation is stable and consistent, significantly enhancing processing efficiency.

While the new energy vehicle industry is developing rapidly, GW Laser provides a series of excellent solutions for the processing of high-reflectivity materials such as copper and aluminum that are widely used in batteries, motors, and electronic control systems. GW Laser will continue to innovate and drive the processing of high-reflectivity materials to leap from "experience reliance" to "intelligent decision-making", providing a reliable technological engine for global high-end manufacturing.