With the rapid development of the handheld laser welding market, a large number of handheld laser welding machines that use water-cooled cooling methods have been sold to the market in recent years. Compared to the external dimensions of traditional welding machines, the existing water-cooled handheld laser welding machines still make customers feel too bulky due to their equipment volume and weight, and frequent maintenance issues continue to make users suffer. When users expect handheld laser welding machines to faceMiniaturization、Lightweight、Maintenance freeThe key breakthrough difficulty in the development trend of water-cooled handheld laser welding machines lies in the use of water-cooled heat dissipation.

The current development of handheld laser welding machine technology in the industry is crucial forAir cooling and heat dissipationThe call for methods is particularly evident, hoping to further make laser handheld welding machines more lightweight, miniaturized, and maintenance free through air-cooled heat dissipation technology, improve the user experience, and make it closer to the traditional welding machine experience. Therefore, two different air-cooled cooling solutions have emerged on the path of air-cooled cooling technology. Which solution can better meet the cooling needs of the product, and which solution is more stable and reliable?

01The Heart of Laser: Semiconductor Laser Chips

The most important component in handheld laser welding machines is the fiber laser, and regardless of the heat dissipation method, it is necessary to ensure good heat dissipation of the fiber laser. The core of heat dissipation in the fiber laser is the semiconductor laser chip in the laser, which can be described as the heart of the laser. If the laser chip cannot obtain effective heat dissipation, it means that the risk of chip failure increases and the power attenuation increases during long-term use, This affects the service life of handheld laser welding machines and is an extremely critical component. In the current technological development situation, the working life of laser chips will rapidly decay with the increase of temperature. The normal working temperature of the chip itself needs to be maintained within 80 ℃, and the generally safe working temperature should be around 60 ℃.

(Semiconductor laser chip)

02Forced air cooling vs. direct air conditioning cooling

Firstly, let's understand the advantages and disadvantages of forced air cooling in handheld laser welding machines;

advantageForced air cooling technology is the process of transferring heat to an aluminum radiator through the conduction of heat, which is then blown by a fan to rapidly flow ambient air, thereby achieving natural heat transfer to the radiator. Compared to water-cooled cooling technology, air-cooled cooling does not require additional water cooling boxes, which can reduce the number and volume of equipment.

DisadvantagesDue to the use of natural convection heat transfer, its heat dissipation efficiency is significantly affected by environmental temperature, and cannot be guaranteed in high temperature environments, resulting in an increase in semiconductor laser chips and a decrease in their service life, which cannot meet the continuous and reliable operation in high temperature environments.

Why choose laser processing? Why choose fiber laser?

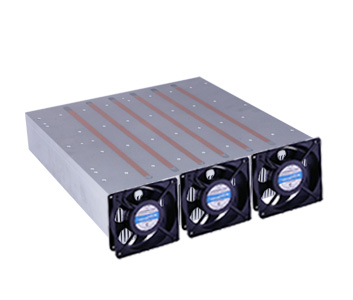

(Traditional passive air-cooled cooling scheme)

Why is it said that forced air cooling cannot guarantee the lifespan and even failure risk of laser chips under high temperatures?

The semiconductor laser chip, as the core component, is encapsulated in a sealed metal shell to form a complete semiconductor laser pump. During operation, a large amount of heat is released. If a 1500W laser is operated at full power, based on the pump electro-optical efficiency of 55%, the semiconductor pump heat dissipation power is approximately 2100W. When the ambient temperature is 30 degrees Celsius, the temperature of the semiconductor pump shell is around 44 degrees Celsius, At this point, the temperature of the laser chip can reach 75 degrees Celsius or above. If the ambient temperature reaches 35 degrees Celsius or above, the working temperature of the laser chip will be higher than 80 degrees Celsius, facing a very high risk of failure. Therefore, for the traditional forced air cooling cooling cooling method, the heat from the left and right sides of the 2500W machine needs to be naturally convection through an aluminum heat sink for heat exchange, which is extremely difficult, Plus the risk of failure of laser chips during high-temperature operation,Unable to meet the long-term reliable continuous operation of the equipment.

(Changes in laser chip temperature at different temperatures compared to traditional air-cooled cooling schemes)

Let's learn more about itActive air conditioning direct cooling and heat dissipation technologyAdvantages and disadvantages of handheld laser welding machines

advantageThe principle is to combine an air conditioning compressor with a fiber optic laser, compress the gaseous refrigerant into a high-temperature and high-pressure gaseous state through the air conditioning compressor, and send it to the condenser for cooling. After cooling, it becomes a medium temperature and high-pressure liquid refrigerant. The medium temperature liquid refrigerant is throttled and depressurized by an expansion valve, becoming a low-temperature and low-pressure gas-liquid mixture. After absorbing heat inside the laser, it vaporizes and becomes gaseous, Then return to the compressor to continue compression and continue circulating for refrigeration. During heating, the four-way valve causes the flow direction of Freon in the condenser and evaporator to be opposite to that during cooling, thereby achieving the heating effect.

Disadvantage: Due to the adoption of a technology principle similar to variable frequency air conditioning, its manufacturing cost is higher than the forced air cooling heat dissipation method of ordinary radiators, and secondly, the equipment weight is slightly higher.

(Forced air cooling vsAir conditioning direct coolingComparison of Two Cooling Methods

03Three core advantages, redefining a new benchmark for air cooling technology

For the more economical forced air cooling technology,Active air conditioning direct cooling and heat dissipation technologyThere are three core advantages:

1Ultra low power attenuation, stable performance, and long-lasting doubling

Industry insiders know that laser chips areSevere irreversible damage will occur above 80 ℃. Thanks to the excellent intelligent temperature control system of "active air conditioning direct cooling technology", it can ensure that the key laser chip in the semiconductor pump of the equipment can continue to work below 70 ℃ under full power and long-term continuous working conditions. After continuous operation for one year,Power attenuation ≤ 5%!However, traditional forced air cooling technology cannot achieve real-time temperature control, and the temperature of the laser chip cannot be controlled within a reasonable range, resulting in a much higher power attenuation of forced air cooling technology equipment than active air conditioning refrigeration technology. This can damage the laser chip and shorten its service life, and in severe cases, directly burn out the laser equipment and make it unusable. Products that use active air conditioning refrigeration technology can perform better in terms of service life and power attenuation, greatly improving the service life of user equipment and reducing costs.

2Fearless of extreme cold and heat, efficient heat dissipation, challenging limits

Due to the fact that forced air cooling relies on the rapid flow of surrounding air to remove internal heat from the equipment, forced air cooling technology is greatly affected by environmental temperature. Changes in weather during hot or cold seasons, as well as regional climate in the south or north, can have a significant impact on the efficiency and stability of forced air cooling equipment, and even directly stop working, affecting user processing efficiency and normal equipment use. The active air conditioning refrigeration technology adopts an independent compressor direct cooling scheme, which ensures strong heat dissipation even in extreme weather conditions. Innovative proposal of Guanghui LaserACC intelligent temperature control technologyTo ensure that the internal temperature of the laser is always stable, thus safeguarding the stable output of the fiber laser equipment.

3Higher heat dissipation capacity, continuously breaking through the upper limit of laser heat dissipation power

As the power of the fiber laser increases, the thermal energy generated will also increase in a straight line. At present, the maximum power of fiber lasers using forced air cooling technology on the market is 1500W. If higher power lasers use forced air cooling technology, they will not be able to take away the heat generated by the equipment, resulting in high internal temperature of the fiber laser and inability to work properly.

During the 2023 Munich Optoelectronics Exhibition in GermanyGuanghui Laser has once again set a new record in the power range of air-cooled technology, and has released tens of thousands of watts of air-cooled products to the world:Active air conditioning direct cooling 12kw fiber laserThe overall heat dissipation power consumption of the machine is greater than 17KW, and the temperature control is still stable, reliable, and accurate, truly breaking through the bottleneck of high-power laser heat dissipation technology, greatly improving the stability of fiber laser operation power. The long-term operation of the equipment is maintenance free, and the maintenance of the water-cooled heat dissipation system is troublesome, making users more worry free and eliminating maintenance troubles.

Optically beneficial laser“Active air conditioning direct cooling technology”Since its release in July 2021, the installed sales volume has exceeded 3000 units, and equipment failures caused by cooling systems are almost zero. The reliability of long-term cooling has been fully verified in the market, truly achieving efficient cooling, intelligent temperature control, and closed-loop control.

At this point, which company is strong in the heat dissipation technology of handheld laser welding machines? Through data comparison and technical differences, the huge advantages of the "direct cooling heat dissipation method of air conditioning" can be clearly compared, which meets the customer's needs for equipmentMiniaturization、Lightweight、Maintenance freeOur pursuit, while greatly ensuring the long-term reliability of equipment operation, is the most correct choice for users!

From continuous exploration and innovation focused on 976nm technology to active air conditioning direct cooling technology solutions, Guanghui Laser has always adhered to technological innovation, with“Making lasers a universal and affordable tool”For the mission, provideHigh performance, high efficiency, and high qualityLaser technology and solutions. In the future, Guanghui Laser will continue to focus on active air conditioning direct cooling technology, leading the latest development trend of air cooling technology, and effectively launching higher coverage from the perspective of usersMore full power, harder quality, and more stable performanceLaser products.