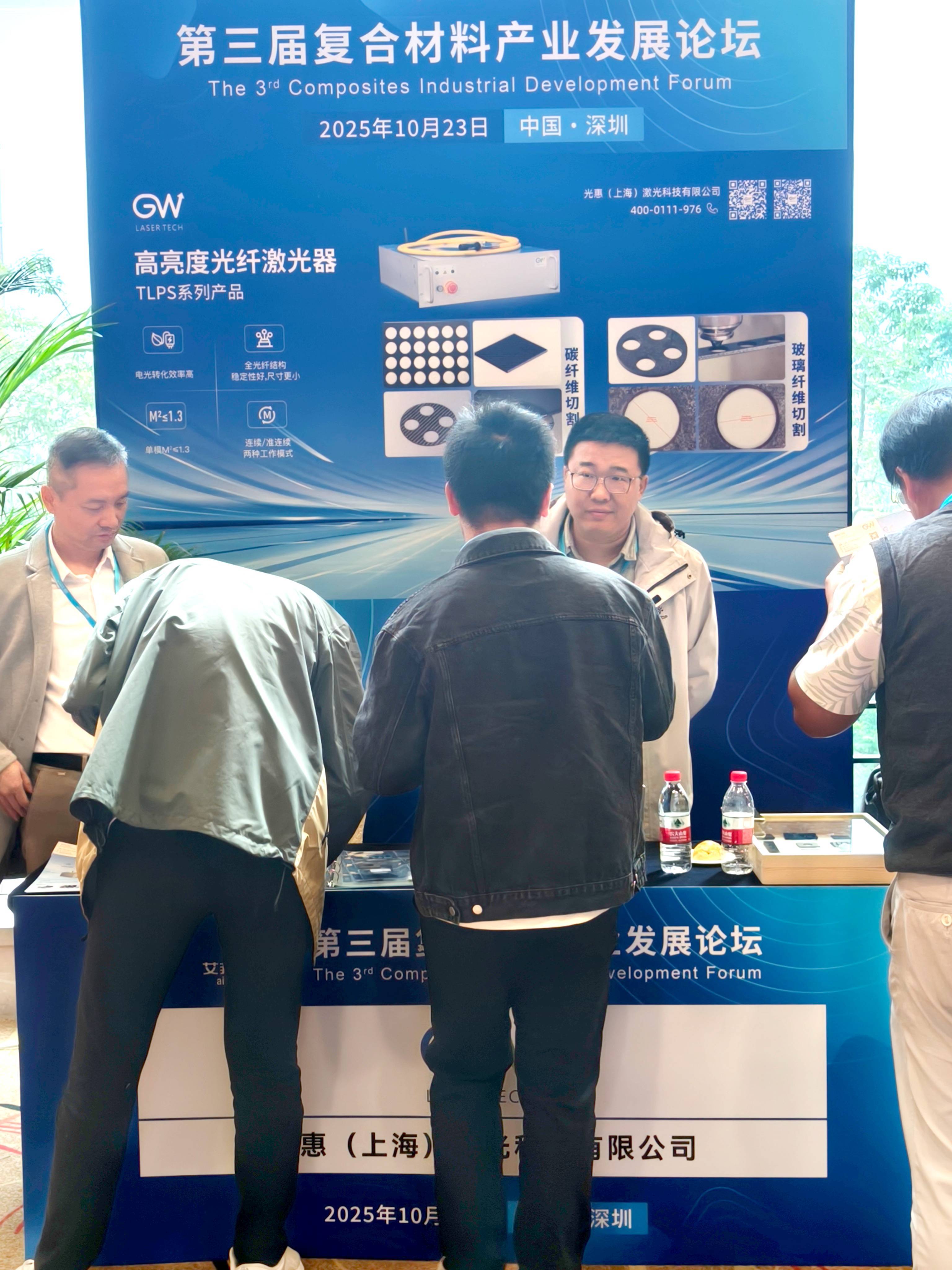

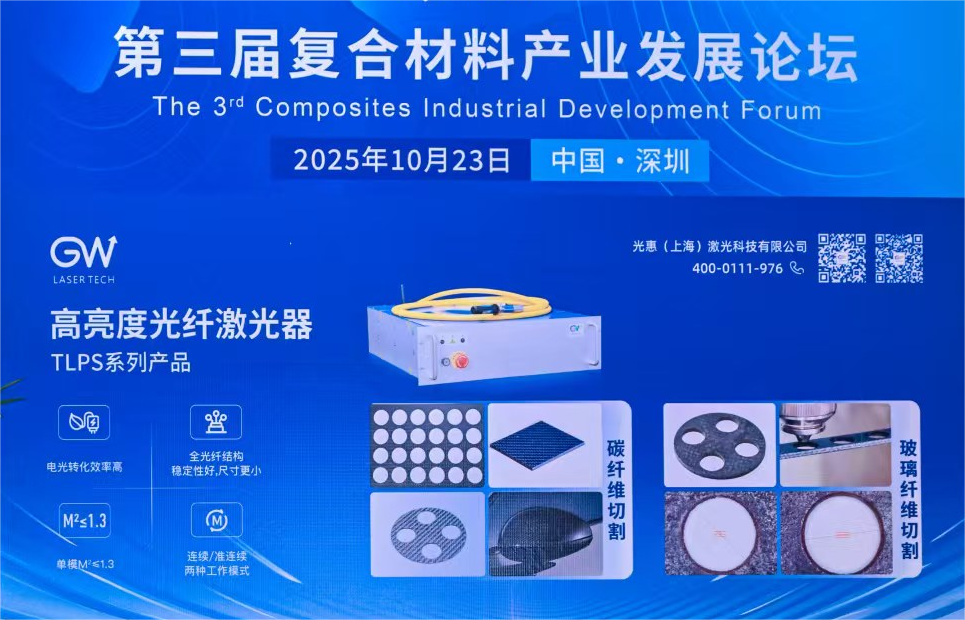

October 23 – The Third Composite Materials Industry Forum concluded successfully in Shenzhen. As a core sponsor, GW (Shanghai) Laser Technology Co., Ltd. actively participated with its high-performance fiber laser solutions, engaging with experts, scholars, and industry leaders from aerospace, new energy, automotive manufacturing, and other sectors to explore technological breakthroughs and industrial applications of thermoplastic composites.

-------------------GW Laser-------------------

<01.>

Laser Technology Driving Material Innovation: Focusing on Industry Pain Points

Centered on the theme of "Thermoplastic Composites," this year’s forum delved into process innovations for high-performance materials such as carbon fiber and glass fiber. At the exhibition, GW LaserTech highlighted precision laser solutions for cutting and welding composite materials. For instance, addressing common challenges like edge burning and delamination in high-precision carbon fiber composite cutting, GW’s self-developed small-core-diameter beam output technology and intelligent power control system achieve clean, micron-level precision cutting, significantly improving material utilization and yield. In thermoplastic composite welding, the non-contact nature of laser processing avoids stress concentration issues caused by traditional mechanical fastening, offering greater flexibility for lightweight structural design.

-------------------GW Laser-------------------

<02.>

Deep Integration of Technology and Applications: Fostering In-Depth Exchange

During the forum, GW LaserTech’s technical team held in-depth discussions with experts from institutions such as the Ningbo Institute of Materials Technology (Chinese Academy of Sciences), COMAC, and BYD, reaching multiple cooperation intentions on innovative laser applications in composite processing. A representative from the aerospace sector noted, “GW’s laser equipment demonstrates remarkable stability in composite drilling and surface treatment, making it particularly suitable for high-precision applications like wing skins and cabin structures.”

-------------------GW Laser-------------------

<03.>

Supporting the "Dual-Carbon" Strategy: Paving the Way for Green Manufacturing

As China advances its carbon peak and carbon neutrality goals, replacing traditional thermoset composites with recyclable thermoplastic materials has become an industry consensus. GW LaserTech supports this transition through energy-efficient laser source design and an intelligent process parameter database, helping customers reduce energy consumption during composite processing while minimizing the use of chemical adhesives. The company’s GW fiber laser-based specialized processing solutions, showcased on-site, attracted significant attention from manufacturers of new energy battery enclosures and UAV fuselages due to their precise temperature control and minimal heat-affected zones.

-------------------GW Laser-------------------

Harnessing Light to Shape Intelligent Manufacturing

The forum not only strengthened GW LaserTech’s brand influence in the composite materials sector but also clarified its customer-driven direction for technological iteration. Moving forward, GW will continue to deepen collaboration with industry chain partners, leveraging laser innovation to advance lightweight materials, green processes, and intelligent manufacturing, thereby injecting new momentum into strategic sectors such as low-altitude economy, new energy, and high-end equipment.

0

0