As an indispensable key process in the manufacturing industry, welding technology is widely used in aerospace, shipping, rail transport and other fields. Laser handheld welding machine because of quick start, high welding quality, flexibility and many other advantages, for the user to bring an unprecedented welding experience, the market compound annual growth rate of more than 100%.

As a leading company in the field of welding technology, GW Laser from the customer, around the handheld welding should have “portability, high efficiency, high precision, multi-functional applications, safety” and other characteristics, and constantly committed to R & D and innovation, the launch of a full range of intelligent handheld laser welding machine. By now, GW Laser will provide two series of handheld welding products, forced air-cooled and active air-conditioning direct cooling, customers can choose according to their own needs.

01 High-efficiency cooling, handheld welding tool

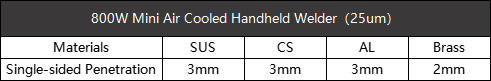

The new forced air-cooled handheld welding machine covers 500W, 800W, 1200W power range, using 3D phase change cooling technology, according to the air-cooled plate temperature, intelligent variable speed fan, while with high temperature chip technology programme, to meet most of the customer’s daily operating environment. New internal structure design, built-in or external wire feeder dual scheme for customers to freely choose, and the wire feeder control board is integrated by the motherboard, which greatly improves the user experience. New appearance design, volume <0.06m³, small footprint, easy to move.

In terms of performance, it adopts ABR super anti-high-reflective technology, which can easily weld common steel (such as carbon steel, stainless steel, galvanised steel, etc.), as well as aluminium alloy, brass and other high-reflective materials.

Meanwhile, with the self-developed gun head of GW Laser, it is small in size and light in weight, and the welding process does not tire your hands, which perfectly meets the needs of daily welding operations. With the self-developed SMAT intelligent operating system, built-in 55 groups of application process data packages, according to the application scenarios to choose, can quickly get started, without the need for a welder’s certificate, you can achieve beautiful and consistent high-quality weld seam.

Highly integrated design, operation is more lightweight, with 7-inch industrial-grade LED touch screen, you can easily set the power, mode selection, fault display, etc., preset welding process parameters, support for user-defined, integrated wire feed control and other operations, more convenient to use.

Safety protection, equipped with input air pressure detection, welding head sensing / light, LOOP safety lock and other functions, all-round protection of user safety. At the same time, the equipment can be connected to WIFI and mobile phone applet interconnection, easy to achieve remote authorisation to use, parameter settings and other functions.

02 Continuous Welding, Continuously Excellent

GW Laser has launched the economical intelligent laser handheld welding series (LS series), covering 800w, 1200w and 1500w power band, with economy as the core, taking into account the high quality and low price.

Adopting active air-conditioning direct cooling technology, no need for water cooler, low failure rate of the whole machine, maintenance-free, no need to worry about the operating environment, can fully meet the customer’s daily production use requirements, so that the customer’s production line to maintain efficient operation. Not only that, our economical product line still maintains high electro-optical efficiency to help customers reduce costs and improve productivity, suitable for welding a wide range of materials, widely used in kitchen and bathroom, guardrail, doors and windows, and other hardware welding market.

![]()

It can run continuously for 24 hours for a long time to ensure the stable work of laser handheld welding. Welding effect is good, the melting depth is deeper, the weld seam is beautiful without deformation, no need to carry out subsequent processing, welding steel, aluminium and other materials melting depth up to 3.5mm; welding copper and other high anti-materials, the melting depth can reach up to 3mm.

GW Laser has launched a full range of laser handheld welding products. Its advanced technology, flexible design, intelligent control system and global certification guarantee make it an ideal welding partner for customers. GW Laser will adhere to the mission of “LASER AS A TOOL” and continue to provide customers around the world with a full range of high-quality, high-efficiency, cost-effective laser handheld welding products.

GW Laser has launched a full range of laser handheld welding products. Its advanced technology, flexible design, intelligent control system and global certification guarantee make it an ideal welding partner for customers. GW Laser will adhere to the mission of “LASER AS A TOOL” and continue to provide customers around the world with a full range of high-quality, high-efficiency, cost-effective laser handheld welding products.

0

0