This week, most parts of the country experienced a new round of cooling, with temperatures exceeding 10 degrees in many areas. As a more precise processing equipment, lasers are prone to working or storing in environments below 5 ℃, which can cause internal cooling structures and optical components to malfunction due to low temperatures. When the temperature reaches 0 ℃, it may cause deformation or rupture of internal pipelines in the water cooling system, leading to equipment failure. So, the key points for winter maintenance and protection of lasers areAnti freezing and low temperature protectionSo how to operate it?

No.1 Antifreeze measures

1Normal use during the day, power-saving without power outage at night, with the water cooler temperature set above 0 ℃;

2The working environment of the laser should be kept in the temperature range of 25 ± 3 ℃ as much as possible to ensure that the laser is always in the optimal operating environment;

3Antifreeze can be added in a timely manner to avoid cracks caused by freezing in the cold water pipeline, which can lead to coolant leakage. If the temperature drops below 0 ℃, use antifreeze for all cooling water;

4The storage temperature of laser and other equipment should be kept above 5 ℃ as much as possible;

5When not in use for a long time or in a state of power outage, drain the water in the water cooler and store the equipment in an environment above 5 ℃.

No.2 Water cooling machine drainage method

Step 1:Before draining, turn off all power supplies, open the drain valve behind the chiller, and drain the accumulated water inside the chiller;

Step 2:Remove the inlet and outlet pipes behind the chiller and mark them for accurate reinstallation;

Step 3: Unscrew the filter element of the chiller and drain the accumulated water inside the filter element;

Step 4Connect 0.2MPA (2KG) gas to one end of the water pipe and drain the accumulated water in the laser.

Attention:

If you need to use an air gun to blow and drain water, you need to open all interfaces (including the water inlet) in advance, and use the air gun to blow gas in from the inlet, not from the outlet. The pressure of the drainage gas should not be too high, otherwise it may damage the laser. It is necessary to ensure that all accumulated water is thoroughly drained to prevent residual liquid from freezing and damaging water cooling pipelines and components.

No.3 Precautions for using antifreeze

1. Antifreeze should not be used for a long time as it has a lifespan and may spoil over time. After the weather warms up, it is necessary to drain it, clean the pipeline, and replace it with ionized water;

2. Different brands or varieties of antifreeze should not be mixed. Different brands of antifreeze have different chemical components, and mixing may cause chemical reactions, loss of antifreeze effect, and residual pollution after the reaction;

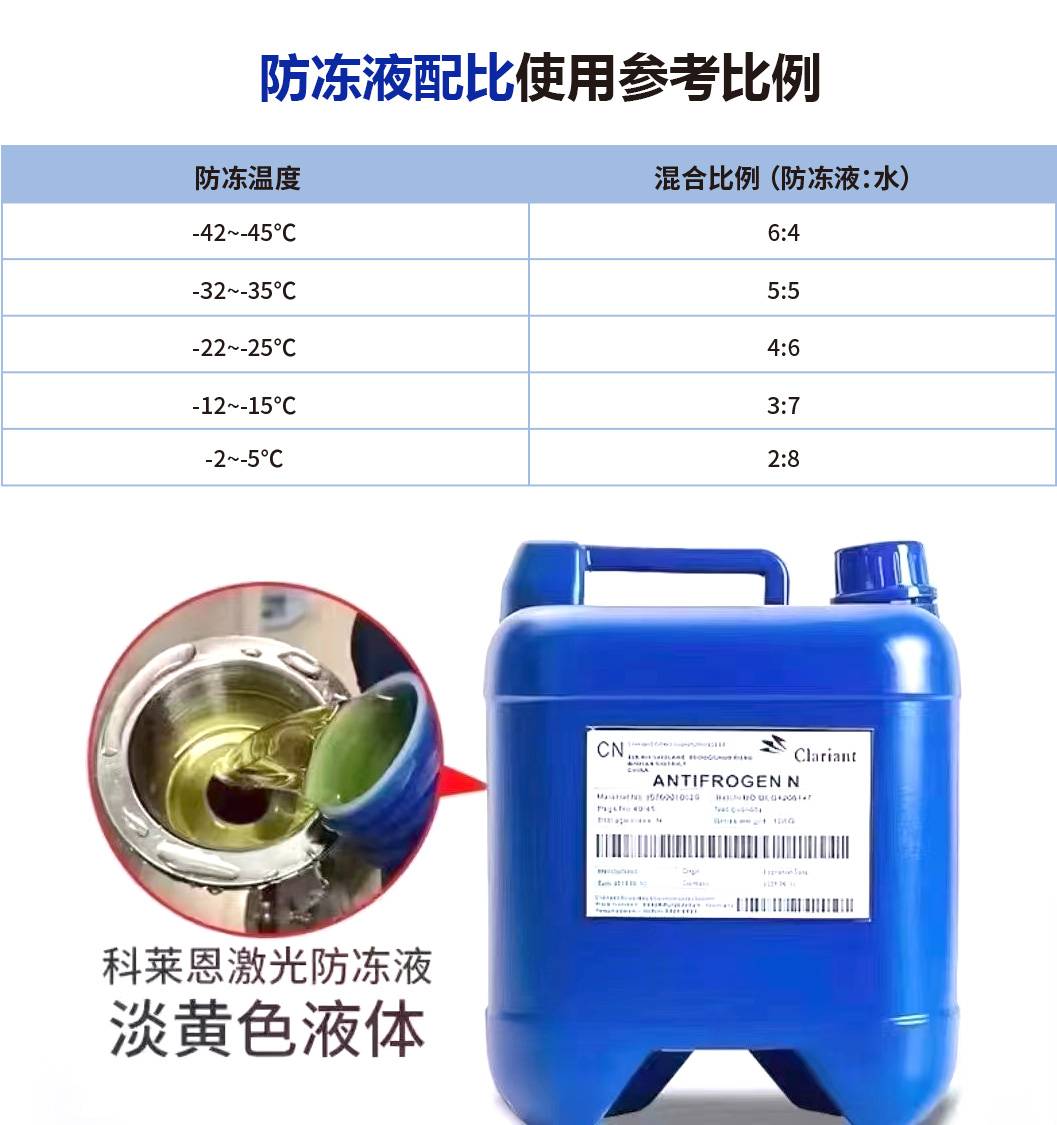

3. It is recommended to choose the brand and proportion of antifreeze, and choose the CLARIANT brand's Antirogen-N ethylene glycol water antifreeze.

No.4 Precautions for starting up in winter

1. Ensure that the indoor temperature is between 5-35 ℃ before the laser equipment can be turned on and used;

2. Check if the water cooling pipe is frozen, and if it is frozen, the laser equipment cannot be turned on;

3. If there is ice formation, please turn on the air conditioning or heating facilities, adjust the ambient temperature of the laser equipment to 5-35 ℃, and let it stand for more than 4 hours. Only after the ice naturally melts can the next operation be carried out. Do not use violent de icing to avoid damaging the equipment hardware;

4. After confirming that the laser equipment has not frozen, it is necessary to first turn on the chiller for preheating;

5. Wait until the circulating temperature of the chiller reaches normal temperature (recommended temperature: around 25 ± 3 ℃) before turning on the laser;

6. After starting up normally, adjust the energy to below 30%, preheat the idle light for about 10 minutes, and then proceed with normal production operations.

Although the cold may strike, service depends on enthusiasm. Guanghui Laser always adheres to the principle of "customer centeredness", and our after-sales team provides 24-hour uninterrupted service to accompany you through every season! If you have any equipment or other issues, please call the toll free hotline at 4000-11-976.