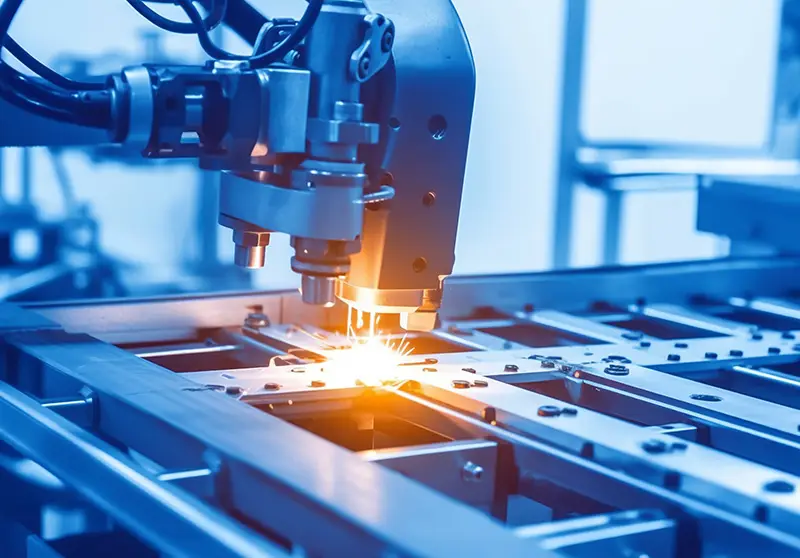

Laser welding

Laser welding is a processing method that uses a high-energy-density laser beam as a heat source to heat the workpiece, and uses pressure or no pressure, with or without filling material, to achieve atomic bonding of the workpiece. Laser welding includes laser self-fusion welding (including high-brightness lasers, FRM lasers, shutter multi-optical output lasers, and dual-band hybrid welding), laser filler wire welding (laser brazing), and laser arc hybrid welding.

Laser welding features:

-

High energy density

Lasers can provide high energy density laser beams, allowing the welding process to quickly heat and melt the welding material. -

High focus

The laser beam can be focused through optical elements such as lenses, making the energy density of the welding point higher to make welding effect better. -

High precision

Laser welding can achieve very precise welding, suitable for tiny welding spots or complex shapes welding. -

Non-contact

Laser welding is a non-contact welding method that can avoid material contamination and deformation. -

Highly controllable

The energy and focus position of laser welding can be precisely controlled by adjusting the parameters of the laser to adapt to different welding needs.

Comparison of advantages between traditional welding and fiber laser

Nowadays, maintaining market competitiveness requires reducing costs, improving efficiency, and maintaining stable part quality, which traditional technologies cannot meet. More and more manufacturers are shifting from traditional welding techniques to more stable parts quality

carbon dioxide arc welding

Double protection welding is suitable for welding various large steel structures of low carbon steel and low alloy high-strength steel. Its welding productivity is high, crack resistance is good, welding deformation is small, and it can be used for welding thin and medium thick plates. During the welding process, there will be more metal spatter.

Double protection welding is suitable for welding various large steel structures of low carbon steel and low alloy high-strength steel. Its welding productivity is high, crack resistance is good, welding deformation is small, and it can be used for welding thin and medium thick plates. During the welding process, there will be more metal spatter.Laser Welding

Laser welding has a high aspect ratio, small weld seam width, small heat affected zone, small deformation, fast welding speed, beautiful weld seam, and minimal welding spatter.

Laser welding has a high aspect ratio, small weld seam width, small heat affected zone, small deformation, fast welding speed, beautiful weld seam, and minimal welding spatter.

Gas Tungsten Arc Welding (GTAW)

GTAW is a manual welding process that requires the use of non consumable tungsten electrodes, inert or semi inert gas mixtures, and individual filler materials, and can only be completed at relatively low speeds.

GTAW is a manual welding process that requires the use of non consumable tungsten electrodes, inert or semi inert gas mixtures, and individual filler materials, and can only be completed at relatively low speeds.Laser Welding

The speed of laser welding has increased by 10 times, the heat input is small, and there is no need for operators to accurately control the arc to control the generation and intensity of discharge, with extremely low requirements for operators.

The speed of laser welding has increased by 10 times, the heat input is small, and there is no need for operators to accurately control the arc to control the generation and intensity of discharge, with extremely low requirements for operators.

Gas shielded metal arc welding

GMAW is a semi-automatic or automatic process that uses continuous wire feeding as electrodes and inert or semi inert gas mixtures to protect welds from contamination. Suitable for larger and poorly installed parts.

GMAW is a semi-automatic or automatic process that uses continuous wire feeding as electrodes and inert or semi inert gas mixtures to protect welds from contamination. Suitable for larger and poorly installed parts.Laser Welding

Laser welding can provide high-precision and controllable welding processes, with the ability to precisely control the laser beam, thereby achieving narrow and deep welds with minimal heat input. It can weld thin materials and precision components without damaging the material.

Laser welding can provide high-precision and controllable welding processes, with the ability to precisely control the laser beam, thereby achieving narrow and deep welds with minimal heat input. It can weld thin materials and precision components without damaging the material.

Application scenarios