Laser Cleaning

Laser cleaning refers to the use of high-energy laser beam to irradiate the surface of the workpiece, so that the dirt, rust or coating on the surface evaporates or peels off instantaneously, and the surface adhesion or surface coating of the cleaning object is removed at high speed and effectively, so as to achieve a clean process. It is a new technology based on the interaction effect between laser and matter, different from the traditional mechanical cleaning method, chemical cleaning method and ultrasonic cleaning method (wet cleaning process), it does not require any CFC organic solvents that destroy the ozone layer, no pollution, no noise, so it’s a a'green' cleaning technology that is harmless to the human body and the environment .

The principle of laser cleaning

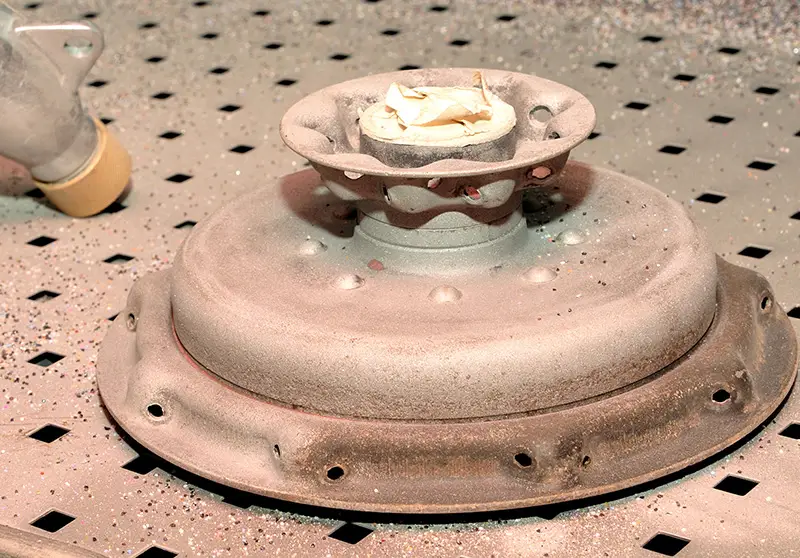

1、Selective evaporation

Different materials have different laser energy absorption rates of specific wavelengths, and when the absorption rate of the adhesion on the surface of the material is greater than the absorption rate of the substrate, the temperature of the adhesion can be instantly raised above the melting point and vaporization occurs through laser irradiation.

Typical applications:

Tire mold cleaning

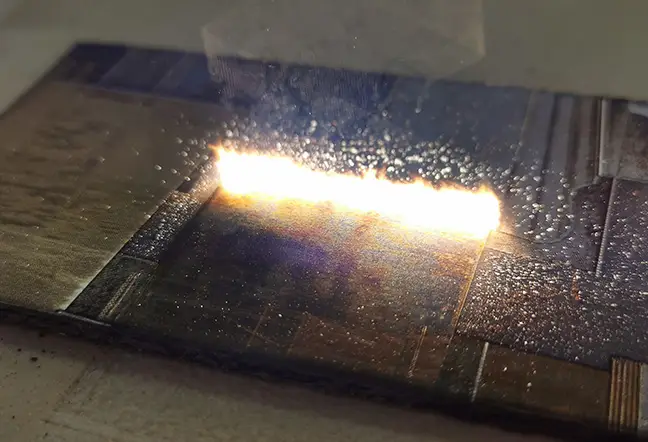

Laser paint removal

Clean up carbon deposits

2、Transient surface heat effect

When the laser pulse scans the surface of the workpiece at high speed, the temperature in this area will increase instantaneously and then decrease, generating thermoelastic pressure. Due to the different thermal expansion coefficients of the adhesion and the substrate, the surface stress is unevenly distributed, so that the adhesion peels off from the substrate.

Typical applications:

3、Shock effect

The high energy density of the pulsed laser vaporizes the adherent and generates instantaneous high temperatures around it, while ionizing the vaporized material to produce plasma. With the continuous irradiation of the laser, the plasma locally generates high temperature and high pressure, and further generates a shock wave, so that the underlying material is microscopically compressed and fragmented. When the laser pulse stops, the plasma instantly generates a negative pressure, which takes away the attached particles generated by the compression.

Typical application: laser removal of metal oxide layers

Comparison of advantages between traditional cleaning and fiber lasers

Nowadays, maintaining market competitiveness requires reducing costs, improving efficiency, and maintaining stable part quality, which traditional technologies cannot meet. More and more manufacturers are shifting from traditional cleaning techniques to using fiber lasers for cleaning

Mechanical Cleaning

Mechanical cleaning is a cleaning method that uses scraping, wiping, and brushing to remove surface pollutants. It has low cleanliness and is very easy to damage the workpiece.

Mechanical cleaning is a cleaning method that uses scraping, wiping, and brushing to remove surface pollutants. It has low cleanliness and is very easy to damage the workpiece.Laser Cleaning

Laser cleaning is a non-contact cleaning method with high cleanliness and extremely low workpiece damage rate.

Laser cleaning is a non-contact cleaning method with high cleanliness and extremely low workpiece damage rate.

Chemical Cleaning

Chemical cleaning removes oxide scale and rust on metal surfaces through acidic solutions. Complex dirt requires repeated cleaning, which can easily damage the workpiece

Chemical cleaning removes oxide scale and rust on metal surfaces through acidic solutions. Complex dirt requires repeated cleaning, which can easily damage the workpieceLaser Cleaning

Laser cleaning does not require chemical cleaning agents and does not produce cleaning waste liquid. It is non polluting to the environment, and due to the lack of drying time, parts can be obtained immediately.

Laser cleaning does not require chemical cleaning agents and does not produce cleaning waste liquid. It is non polluting to the environment, and due to the lack of drying time, parts can be obtained immediately.

Sandblasting Cleaning

Sandblasting cleaning uses compressed air to spray sand of a certain particle size onto the surface of parts with dirt through a spray gun. The sandblasting cleaning environment is not good, there is a lot of dust, and if cleaned for a long time, the sand particles will damage the basic material.

Sandblasting cleaning uses compressed air to spray sand of a certain particle size onto the surface of parts with dirt through a spray gun. The sandblasting cleaning environment is not good, there is a lot of dust, and if cleaned for a long time, the sand particles will damage the basic material.Laser Cleaning

Laser cleaning eliminates the problem of sandblasting media and does not damage the workpiece. It only requires one person to operate, and there is no harm to the cleaning personnel during the operation. The working environment is good.

Laser cleaning eliminates the problem of sandblasting media and does not damage the workpiece. It only requires one person to operate, and there is no harm to the cleaning personnel during the operation. The working environment is good.

Application scenarios