Laser cladding

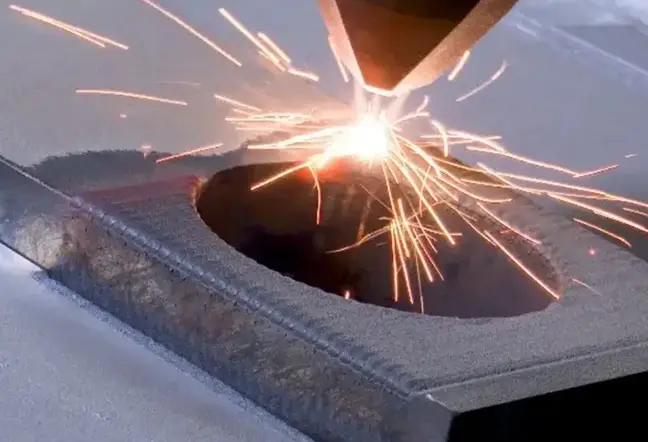

Laser cladding technology is a part surface modification technology. Its essence is to use preset powder method or synchronous powder feeding method to supply cladding material to the surface of the base material, and rapidly melt, expand and solidify under the action of high-energy density laser beam. Form a surface layer with extremely low dilution and metallurgical bonding with the substrate, thereby repairing defects and improving the wear resistance, corrosion resistance, heat resistance, oxidation resistance and other properties of the base layer surface.

Laser cladding technology has the advantages of automated repair, metallurgical combination of the repair layer and the substrate, high strength, small heat injection, small deformation of parts, precise and controllable repair dimensions, etc. It does not pollute the environment, and the performance after repair is greatly improved. This technology has been successfully used in the repair of major key components such as oil transportation equipment, metallurgical rolls, and generator sets, achieving significant economic and social benefits.

Laser Cladding Features:

- Fast cooling speedLow coating dilution rateLow heat input and distortionWide selection range of cladding materialsWide adjustable range of coating thicknessSelective Laser Cladding Automatic control

Laser additive manufacturing applications

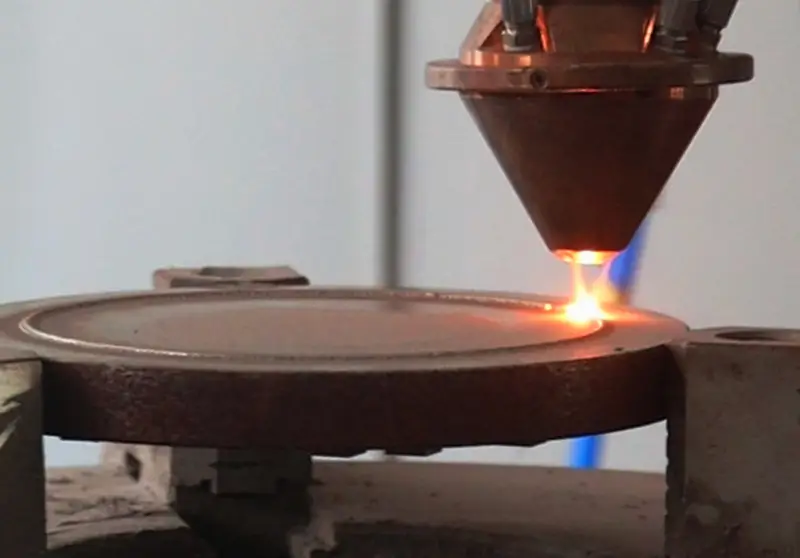

- Product name:Coal machine industry hydraulic column

- Laser:Guanghui laser 6000W laser

- Process:coaxial powder feeding, high-speed cladding, line speed > 10m/min

- cladding channel temperature:about 60℃

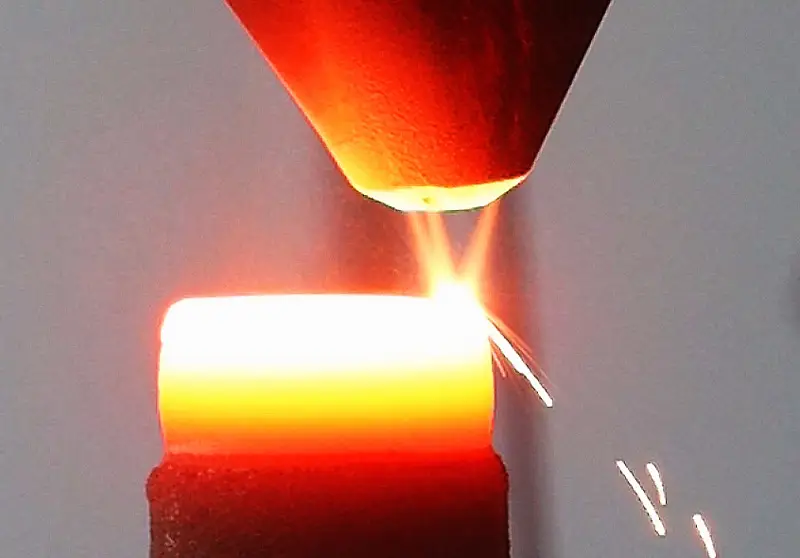

- Product name:Coal machine industry hydraulic column

- Laser:Guanghui Laser 4000W laser

- Process:coaxial powder feeding, conventional cladding, line speed: 1.0~1.5m/min

- cladding channel temperature: about 800-900℃

Comparison of advantages between traditional cladding and fiber lasers

Nowadays, maintaining market competitiveness requires reducing costs, improving efficiency, and maintaining stable part quality, which traditional technologies cannot meet. More and more manufacturers are shifting from traditional cladding technology to using fiber laser cladding

Plasma Cladding

After plasma spraying and melting, the bonding strength is low and the coating is easy to peel off

After plasma spraying and melting, the bonding strength is low and the coating is easy to peel offLaser Cladding

Laser cladding has advantages such as lower dilution rate, better processing flexibility, and less thermal impact on the workpiece

Laser cladding has advantages such as lower dilution rate, better processing flexibility, and less thermal impact on the workpiece

Thermal Spraying

Although the deposition rate of thermal spray coating is high, the powder utilization rate is only 50%. The coating has a porosity of 1% to 2%, and the corrosive medium will corrode the substrate through these voids. Thermal spraying is prone to generating noise and dust pollution during work, which affects the environment and the health of personnel

Although the deposition rate of thermal spray coating is high, the powder utilization rate is only 50%. The coating has a porosity of 1% to 2%, and the corrosive medium will corrode the substrate through these voids. Thermal spraying is prone to generating noise and dust pollution during work, which affects the environment and the health of personnelLaser Cladding

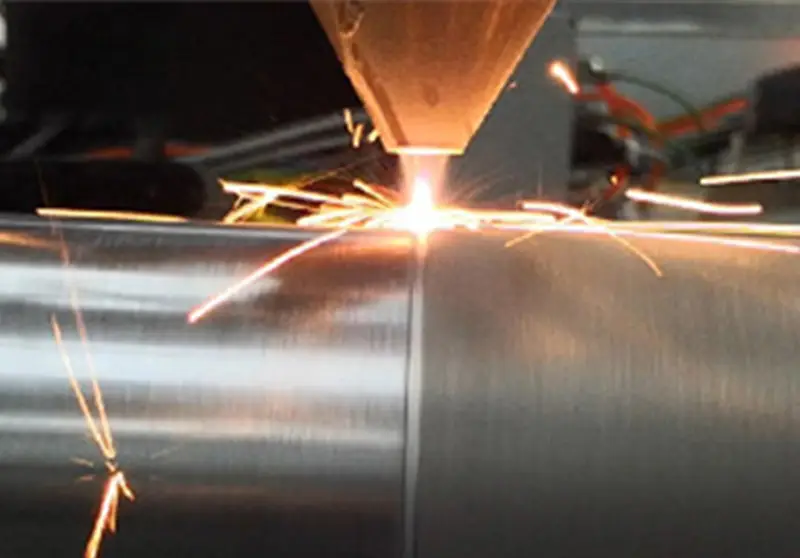

The coating prepared by laser high-speed melting has a dense and non porous structure, and the coating is metallurgical bonded to the substrate, resulting in high bonding strength

The coating prepared by laser high-speed melting has a dense and non porous structure, and the coating is metallurgical bonded to the substrate, resulting in high bonding strength

Surfacing

Surfacing technology can prepare high-quality and defect free metal coatings, with high deposition efficiency accompanied by high energy input, which can induce the transformation of the microstructure and properties of the substrate material and thermal damage

Surfacing technology can prepare high-quality and defect free metal coatings, with high deposition efficiency accompanied by high energy input, which can induce the transformation of the microstructure and properties of the substrate material and thermal damageLaser Cladding

The high-speed laser cladding method absorbs most of the energy by the powder, resulting in less heat input to the substrate and relatively smaller heat affected zone and thermal deformation, making it more effective for cladding thin-walled and thin plates

The high-speed laser cladding method absorbs most of the energy by the powder, resulting in less heat input to the substrate and relatively smaller heat affected zone and thermal deformation, making it more effective for cladding thin-walled and thin plates

Application scenarios