As global manufacturing accelerates toward intelligent and green transformation, achieving efficient production and sustainable development through technological innovation has become a critical focus for the industry. As the global leader in air-cooled 10kW+ laser technology, GW Laser has redefined the performance boundaries of laser equipment with its revolutionary Active Air Cooling (AAC) technology. From the launch of the 12kW AAC laser in 2023 to the upcoming 20kW flagship model in 2025, GW Laser has not only liberated high-power continuous fiber lasers from reliance on water-cooling systems but also elevated laser thermal management to unprecedented heights.

Technical Innovation: A Paradigm Shift in Laser Cooling

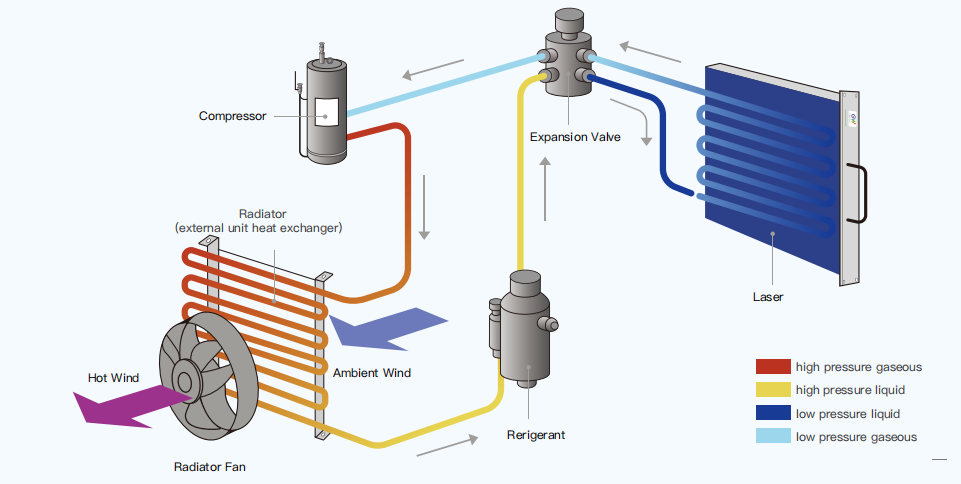

Traditional water-cooled systems have long faced criticism for high energy consumption, bulky designs, and complex maintenance. GW Laser’s proprietary Active Air Cooling (AAC) technology innovatively integrates air conditioning compressors with fiber lasers, establishing a closed-loop temperature control system. The core operational workflow is as follows:

Compression: The compressor pressurizes gaseous refrigerant into a high-temperature, high-pressure state, which is then delivered to the condenser.

Condensation: The high-temperature gas is cooled into a liquid state, dissipating heat through exhaust fans.

Expansion: The high-pressure liquid refrigerant passes through an expansion valve, reducing pressure and temperature to an evaporable state.

Evaporation: The low-pressure refrigerant absorbs heat from the laser module, evaporating into gas and cooling critical components.

Recirculation: The gaseous refrigerant returns to the compressor, restarting the cycle.

Adopting the compressor to control the temperature directly to the laser, it can realize closed-loop control between the control object and the refrigeration system through the intelligent temperature control system, and carry out accurate refrigeration or heating on demand, with low energy consumption. Compared with traditional water-cooled cooling, there is no need for external heat exchange through coolant, no cooling water pollution, pipeline clogging and other problems, better temperature control and maintenance-free.

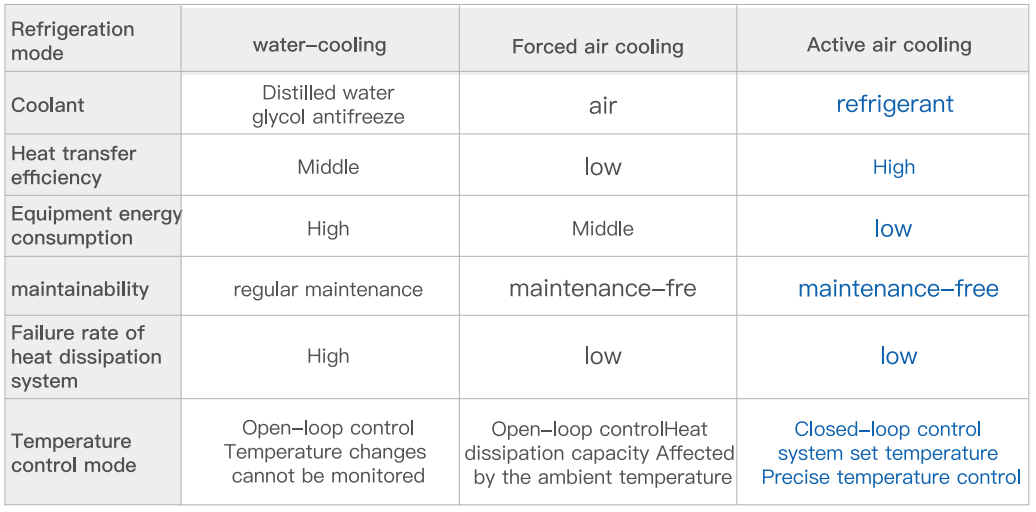

Core performance comparison:

Core Advantages

Four dimensions to empower industrial upgrading

01 Air-cooled 10,000-watt laser technology experts

As the power of the fiber laser rises, the heat generated will also rise linearly. Currently on the market using forced air cooling technology fiber laser power of up to 2000W, higher power band laser if the forced air cooling technology, will not be able to take away the heat generated by the equipment, resulting in high internal temperature of the fiber laser, can not work properly. Following the 12kW laser, GW Laser continues to research, in March 2025 Laser World of Photonics

China for the first time to display the “active air cooling 20kW laser”, breaking through the upper limit of the refrigerant cooling power, to provide users with “refrigerant + water cooling” dual-choice program. We will provide users with a dual choice of “refrigerant + water-cooling” program.

02 Stability and Reliability Double Enhancement

Unlike the water-cooled cooling method, which requires high ambient temperature, GW Laser's active air-cooled laser can work in -20~50℃ environment, which always ensures that the laser chip temperature is in the safe zone under the continuous operation of the high-power laser, and avoids the risk of the laser chip's failure under the traditional air-cooled cooling method when the ambient temperature rises.

In addition, GW laser active air-conditioned direct-cooled laser also adopts ABR super anti-high-reflective technology, which can easily cut common steel (such as carbon steel, stainless steel, galvanized steel, etc.), as well as aluminum alloys, brass and other high-reflective materials. At the same time, the use of CHF condensed high-brightness flat-top technology can output a more uniform distribution of laser energy at higher energy densities, especially at 10,000 watts or more continuous power output, the laser output is more stable, and it can reduce the Gaussian energy input to the optical lens of the index requirements and the risk of damage. In the application of thicker plate cutting, CHF technology can utilize the feature of higher energy density, which makes the 10,000-watt product series of GW Laser have excellent performance of thick plate cutting to realize bright surface cutting, and at the same time take into account the application process requirements in specific scenarios.

03 Energy Saving and Cost Reduction, Remarkable Economic Benefits

GW laser active air-conditioning direct-cooled laser adhere to the “energy efficient” concept of environmental protection, from the user's cost of use and electricity costs, active air cooling laser can effectively reduce the user's cost of electricity, and at the same time to avoid the traditional water-cooled heat dissipation brought about by the cost and maintenance problems, free of water-cooled daily use and maintenance costs, to help customers realize cost reduction and maintenance costs, to help customers realize cost reduction. Maintenance costs, to help customers realize cost reduction and efficiency.

04 High system integration

GW laser active air-conditioned direct-cooled lasers can be integrated with GW self-developed handheld laser welding system and third-party laser cutting or welding system, can be used with the laser processing head, galvanometer, etc. with robots, machine tools, etc. for system integration, to do laser fine cutting, precision welding processing, widely used in 3C, hardware, medical, automotive, aviation and other fields.

GW Laser's active air-conditioning direct cooling technology is not only an innovation in heat dissipation mode, but also a systematic reconstruction of industrial manufacturing efficiency, cost and sustainability. This technology has won a number of awards, including the “Best Fiber Laser Technology Innovation Award”, and will continue to lead the industry's technological development, injecting new momentum for the global industrial upgrading.

0

0