With provinces like Shanxi and Hebei issuing frequent cold wave alerts, and meteorologists predicting an exceptionally cold winter for 2025, extreme low temperatures pose a serious challenge to industrial equipment. GW LaserTech issues this winter protection advisory to all valued customers and partners to ensure your equipment operates efficiently through the season.

Q: How to Prevent Laser Freezing?

As the core component of precision equipment, lasers are highly sensitive to low temperatures. If the ambient temperature drops below the minimum operating threshold (typically around 5°C), cooling water can freeze and expand, causing irreversible damage to internal water-cooling lines and key components. Key protection measures include: 1、Maintain Ambient Temperature The optimal operating temperature for lasers is around 25±3°C. Ensure the environment for the laser and its cooling system remains above the minimum operating temperature, using stable heating systems or industrial heaters if necessary. 2、Use Antifreeze Add antifreeze to the cooling water to prevent freezing and pipe rupture. For equipment in non-heated environments or areas prone to extreme cold, replace the coolant with a specialized antifreeze solution. 3、Long-Term Shutdown Procedures For extended equipment shutdowns, completely drain the cooling system and store the equipment in an environment above 5°C.

Q:How to Properly Drain Equipment?

For all systems potentially exposed to low temperatures—including water, air, and hydraulic lines—thorough drainage is essential to prevent freezing and cracking. Follow this winter shutdown drainage guide:

1、Power off the laser and cooling system.

2、Disconnect inlet and outlet water hoses. 单模组激光器

多模组激光器

3、Open the cold water machine filter core and drain internal water.

4、Open all system drain and exhaust valves. Use compressed air (0.2 MPa / 2 kg) to blow out residual liquid from the laser.

【Note】 Pay special attention to low-lying areas prone to water accumulation, such as pipe bends, valves, and filters. Ensure protective gases supplied to the cutting head are adequately dried to prevent ice blockages. Always introduce air from the inlet, not the outlet, and avoid excessive pressure to prevent damage.

Q:How to Choose Antifreeze?

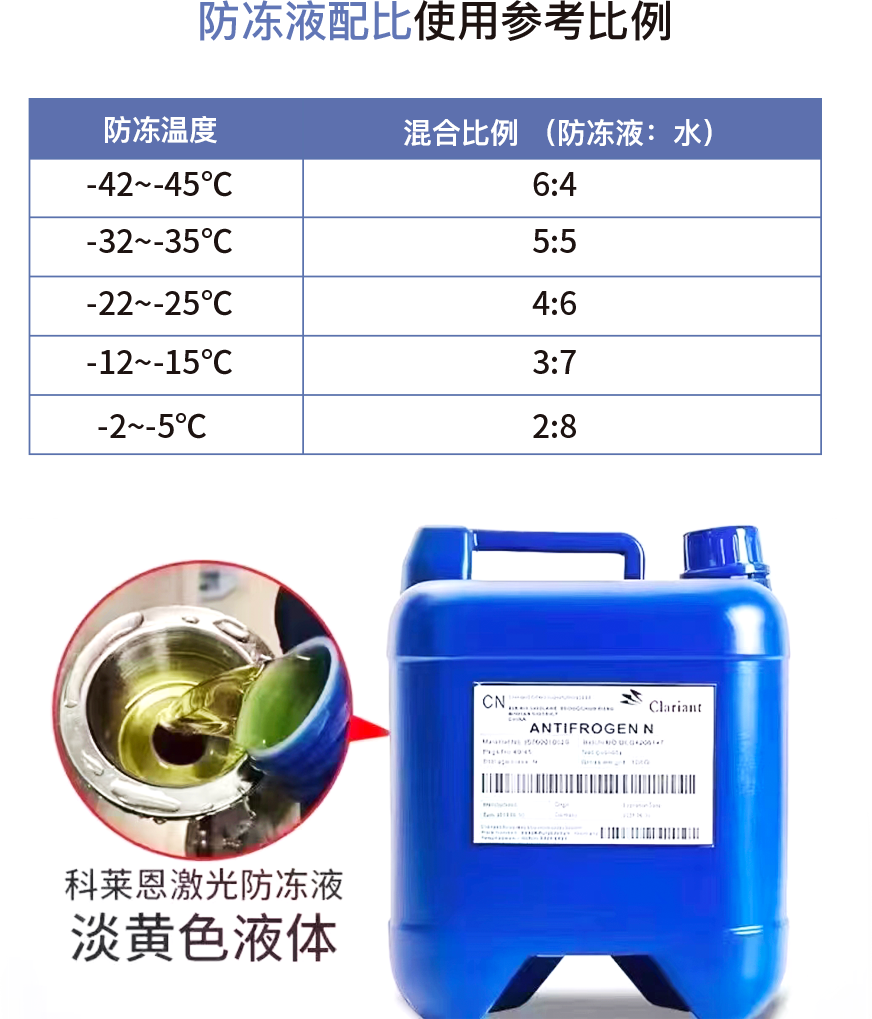

Selecting and using the right antifreeze is critical for equipment protection in winter. 1、Use Industrial-Grade Antifreeze Choose recommended or certified industrial antifreeze, such as CLARIANT's ANTI-FROGEN-N glycol-water type. Do not use automotive antifreeze, as its formula can corrode seals and components. 2、Avoid Mixing Types Different brands or types of antifreeze may react chemically, reducing effectiveness and causing contamination. 3、Check Freezing Point The antifreeze’s freezing point should be at least 10°C below the historically lowest ambient temperature at your site. 4、Regular Testing and Replacement Antifreeze performance degrades over time. Regularly check key indicators like freezing point and pH value, and replace periodically along with cleaning lines and changing deionized water. 5、Correct Concentration Follow recommended dilution ratios. Too low a concentration reduces protection; too high can impair cooling efficiency or cause sedimentation.:

Q:Winter Startup Precautions?

In cold weather, start equipment gradually using a "slow ramp-up" approach to avoid cold-start damage.: 1、Pre-warm the Environment: Activate heating systems in advance to bring the ambient temperature steadily up to the permitted operating range (5–35°C). 2、Check for Ice: Inspect water-cooling pipes and laser equipment for ice. If found, allow it to thaw naturally in a warmed environment for over 4 hours. Never use force to remove ice. 3、System Preheating: For key equipment like lasers, start the chiller for preheating. Wait for the circulating temperature to reach the normal operating range (around 25±3°C). 4、Gradual Load Increase:Power on the laser and increase the load (e.g., processing power, feed rate) gradually from low to high. Begin by setting energy below 30%, allowing the laser to preheat by idling for about 10 minutes before normal operation. 5、Monitor Closely: During initial operation, closely watch all system parameters (cooling water temperature, pressure, noise, vibration, etc.). Stop immediately if any abnormalities are detected.

GW LaserTech's global service network is ready for this winter. We stand by to provide prompt technical support and on-site maintenance. Your equipment's stable operation is vital to your productivity. For any questions regarding winter protection or operation, please contact us: Service Hotline:400-0111-976 Official Website:https://www.gwlaser.tech Let's work together to ensure your equipment's safety and smooth operation through this winter. Remember: preparing in advance for extreme cold is crucial!

—————— —— END —— ——————

0

0