With the rapid global expansion of the low-altitude economy, UAVs and eVTOLs increasingly rely on lightweight, high-strength composite materials such as carbon fiber, glass fiber, PPS, foam, and rubber. While these materials enhance performance, their precision processing remains a significant industry challenge. GW LaserTech’s high-brightness fiber laser solutions deliver breakthrough capabilities for cutting composites with unmatched accuracy and efficiency.

01 Processing Challenges in Low-Altitude Composites

Low-altitude aircraft require extreme precision, minimal weight, and high reliability—standards often unmet by conventional processing methods.

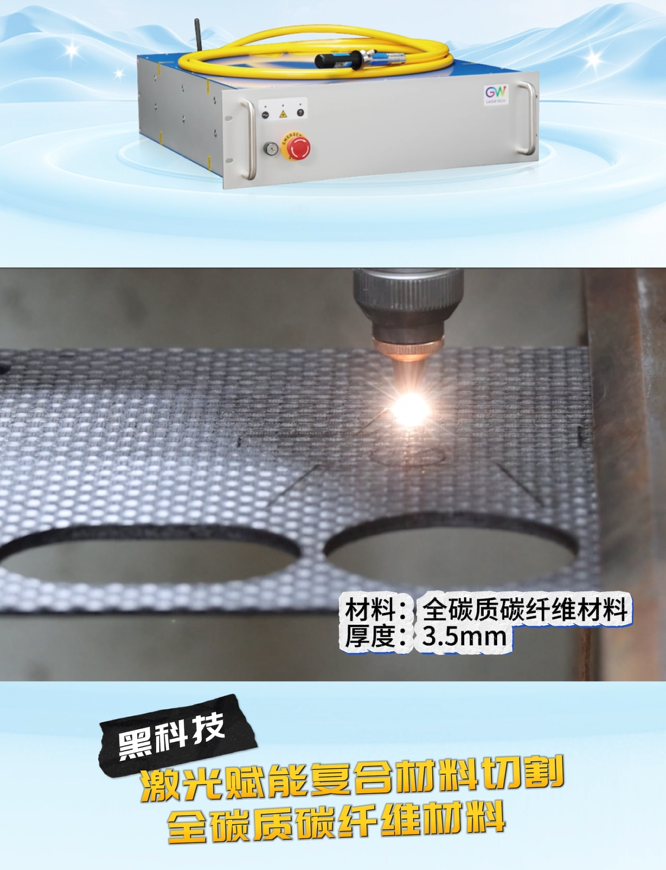

○ Carbon Fiber Composites ○

【Advantages】

· 5x specific strength of steel, 1/4 the density; corrosion and fatigue resistant; enables >30% weight reduction in eVTOL structures.

【Applications】

· UAV load-bearing structures, eVTOL cabin frames, wing skins.

【Challenges】

· Delamination and tool wear with mechanical cutting; carbonization and HAZ >200μm with traditional lasers; dust contamination risks.

○ Glass Fiber Reinforced Composites ○

【Advantages】

· Excellent insulation, 1/3 the cost of carbon fiber, high weather resistance.

【Applications】

· UAV electronics housings, radomes, fairings.

【Challenges】

· Hazardous glass dust from milling; low accuracy (±1mm) and water residue with waterjet; yellowing with CO₂ lasers.

○ PPS ○

【Advantages】

· Withstands >200°C, UL94 V-0 flame retardancy, chemical resistance.

【Applications】

· UAV battery insulation, engine components, electrical mounts.

【Challenges】

· Stress cracking during post-processing; edge melting with thermal knives; UV lasers limited to <1mm thickness.

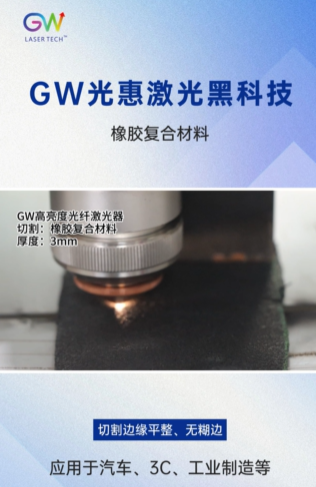

○ Foam & Rubber Sealing Materials ○

【Advantages】

· Superior damping, reliable sealing, lightweight.

【Applications】

· eVTOL cabin seals, landing gear pads, sensor protectors.

【Challenges】

· Burrs and scorching with die-cutting; water residue impairing adhesion; difficulty with complex 3D shapes.

These limitations hinder both production efficiency and performance optimization of low-altitude aircraft.

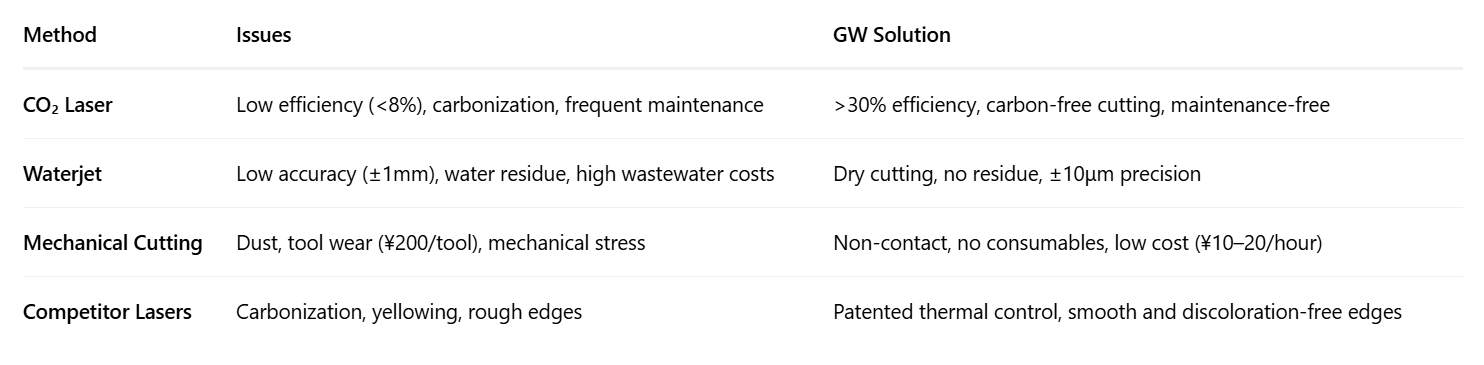

02 Comparative Advantages: Redefining Industry Standards

GW’s proprietary high-brightness fiber lasers overcome these challenges through innovative design:

Beam Quality (M²≤1.3):30μm focal spot enables ±10μm cutting precision with smooth, burr-free edges.

Intelligent Thermal Control:Minimizes HAZ to <30μm, preventing carbonization in carbon fiber and PPS.

ABR Anti-Reflection Technology:Ensures stable processing of high-reflectivity materials like glass and carbon fiber.

Compact All-Fiber Design:Supports continuous/quasi-continuous modes for versatile applications.

UAV Fuselage & Shells

Processing Outcome: Delamination-free cutting of carbon fiber/PPS materials with micron-level accuracy for propeller mounting holes.

Carbon fiber composites, widely used in primary load-bearing structures for UAVs and eVTOL cabin frames, present significant challenges when processing thin skins (e.g., 0.8 mm thickness). GW’s high-brightness fiber laser—integrated with robotic systems—enables precise curved-surface cutting, achieving hole positioning accuracy within ±0.02 mm, meeting stringent aviation assembly standards.

Acoustic & Damping Components

Processing Outcome: Burr-free edges on foam and rubber materials, preserving acoustic and fireproof properties.

For multi-layer composite foam (up to 30 mm thick) used in eVTOL cabins, GW’s unique pulsed laser technology creates a "micro-ablation" effect by optimizing laser parameters. This ensures clean, layer-separated cuts without compromising material integrity, maintaining optimal sound insulation.

Power System Components

Processing Outcome: Dust-free cutting of glass fiber housings, preventing damage to electronic devices.

Motor brackets made of glass fiber-reinforced composites require high dimensional stability and strict weight control. GW’s non-contact laser processing, combined with vision positioning systems, achieves micron-level 3D precision. In practice, this results in bracket flatness within 0.05 mm/m² and weight deviations under ±3 g, ensuring reliable power system performance.

Landing Gear Seals

Processing Outcome: 3D cutting of spring rubber sleeves without burrs, enhancing sealing reliability.

GW’s laser technology precisely controls pulse duration to prevent heat diffusion before material vaporization, critical for elastic specialty rubber. The resulting seals feature lip dimensional accuracy of ±0.01 mm and surface roughness Ra ≤ 0.8 μm, fully complying with aviation sealing requirements.

03 Technical Backing & Global Support

GW leverages vertical integration from chips to modules via R&D centers in Shanghai, Nantong, and Wuhan. With CE/FDA certification and 20,000+ units deployed worldwide, GW’s technology—pioneered by Dr. Ding Jianwu and his team over 20 years of 976nm R&D—ensures reliable, high-performance solutions.

Conclusion

The rapid growth of the low-altitude economy demands higher standards in composite material processing. GW LaserTech’s high-brightness fiber lasers address critical industry challenges with high precision and cost-effective solutions for UAV and eVTOL manufacturing. Moving forward, we will deepen collaboration with global integrators and distributors to jointly advance low-altitude manufacturing technology.

0

0