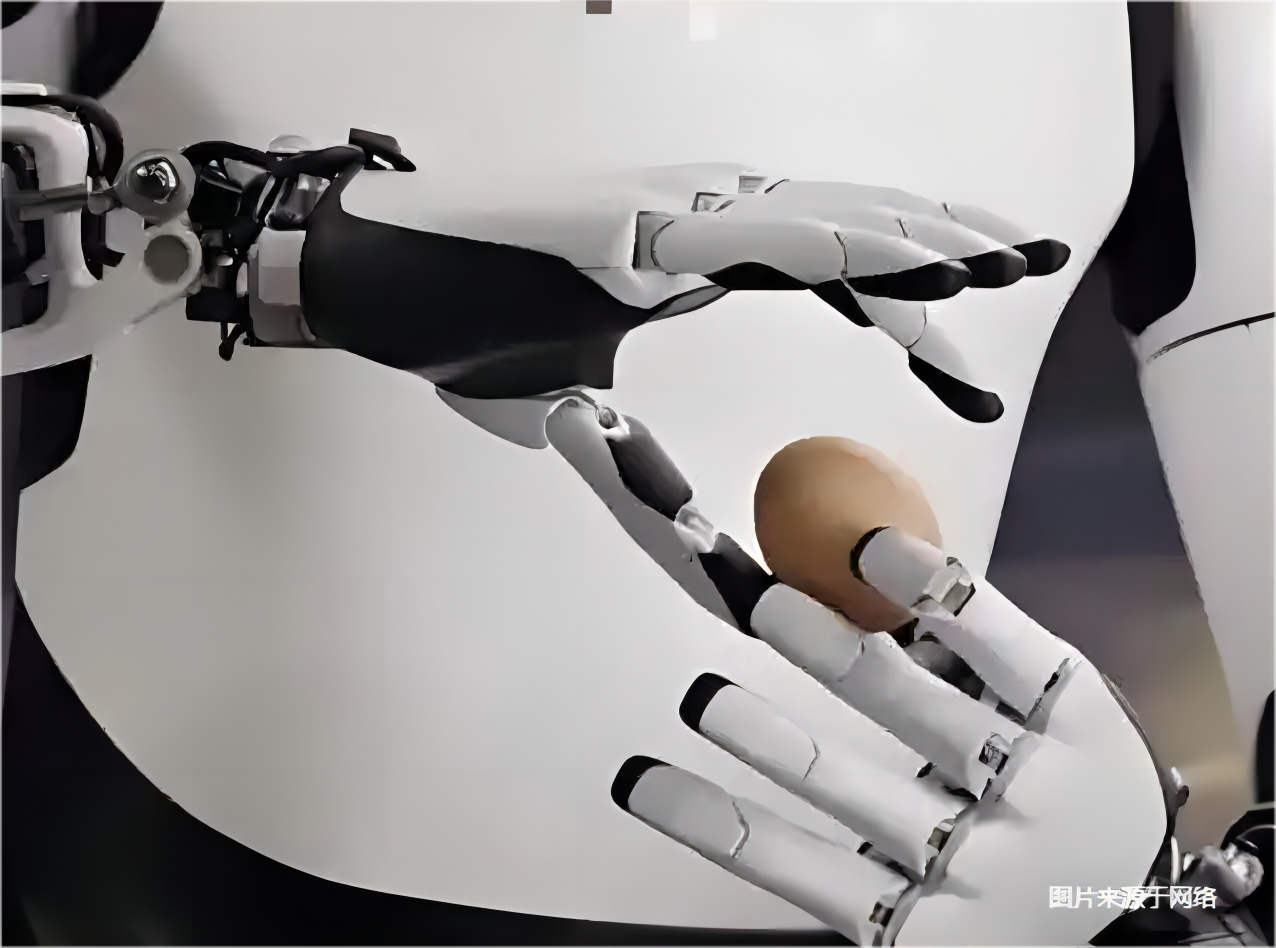

We stand at the dawn of the humanoid robotics industry’s breakthrough. When Tesla’s Optimus Gen-3 deftly grasps tiny objects under the spotlight, or Boston Dynamics’ Atlas performs astonishingly complex movements, one of the core technologies enabling these feats lies within the “dexterous hand”—the ultimate tool for humanoid robots to interact with the physical world and execute delicate tasks. The performance of the dexterous hand directly determines the scope of a robot’s applications and its functional value. Among actuation solutions for dexterous hands, tendon-based systems—often regarded as the “muscles” of robots—have emerged as a key pathway to achieving high degrees of freedom, lightweight design, and cost efficiency.

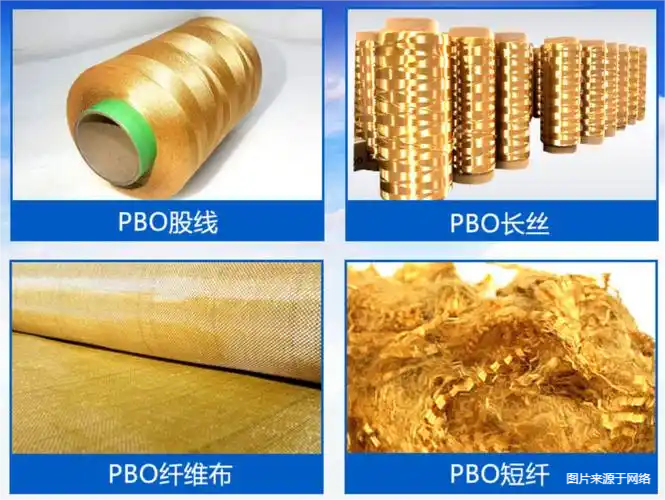

As industry analyses indicate, “tendons account for approximately 30% of the total cost of a dexterous hand,” and their importance continues to grow with technological advancement. Today, material innovation is elevating this critical component to new heights. PBO fiber, with performance metrics surpassing those of traditional ultra-high-molecular-weight polyethylene (UHMWPE), has become the ideal choice for next-generation robotic tendons.

Yet, extreme material performance brings extreme processing challenges. As a team deeply rooted in industrial laser technology, GW LaserTech understands that processing PBO fiber—a true “super material”—with precision, efficiency, and zero damage, poses a major hurdle across the supply chain. How can we analyze and resolve these technical bottlenecks? How can our high-brightness fiber lasers deliver the ultimate solution for high-quality, efficient PBO tendon production—and in doing so, empower innovation in humanoid robotics? These questions drive our latest R&D focus.

Why PBO?

To understand the processing challenges, one must first appreciate the exceptional properties of PBO and the inevitability of its adoption. Key advantages over UHMWPE include:

1. Ultimate Strength & Modulus:

PBO fiber boasts a tensile strength of 5.8 GPa and modulus of 270 GPa—1.7× and 2.4× higher than UHMWPE, respectively. This enables thinner tendons to withstand greater loads and transmit more precise force feedback, significantly improving grip strength and motion accuracy.

2. Superior Thermal Stability:

PBO decomposes at 650°C, far exceeding UHMWPE’s 150°C limit. This ensures dimensional and mechanical stability even under prolonged operation or high motor temperatures, enhancing reliability.

3. Excellent Creep Resistance:

Under a constant 60 N load, PBO can endure for up to 19 years before failure—critical for applications requiring long-term precision and pose retention.

4. Low Density & Environmental Resistance:

With a density of just 1.54 g/cm³ (lighter than carbon fiber) and high resistance to acids and alkalis, PBO is ideal for demanding environments.

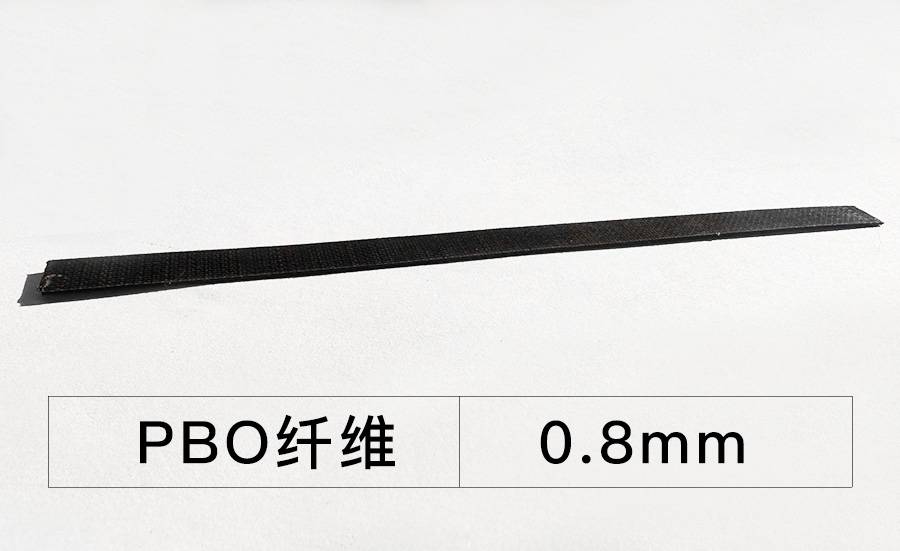

PBO Processing Challenges

Despite its superior properties, PBO’s high thermal resistance and molecular stability make it a notoriously difficult-to-process material. In tendon manufacturing, cutting is a critical step that determines end-face quality, length accuracy, and service life. Conventional methods face serious limitations:

Burrs & Fraying: The high toughness of PBO causes blade-cut edges to fray, creating stress concentration points that accelerate wear and risk failure under cyclic loading (humanoid tendons must endure over 2 million fatigue cycles). Tool Wear & Cost: The hardness and strength of PBO cause rapid blade deterioration, increasing costs and compromising consistency. Crushing & Deformation: Mechanical pressure can crush fiber ends, hindering smooth passage through guides and increasing friction.

PBO tendon cutting requires not just “severing” but high-quality, micro-invasive severing—with minimal heat-affected zone (HAZ), no mechanical stress, and smooth edges. This is the technical barrier every humanoid robotics company must overcome.

High-Brightness Fiber Lasers

GW’s high-brightness fiber laser solution offers precise control over laser energy—enabling clean, high-quality cuts that meet the stringent demands of PBO tendon production. “High brightness” is key: it denotes exceptional energy concentration. Through proprietary beam-shaping technology and optimized core components, GW lasers deliver a near-perfect beam (M² ≈ 1) with uniform energy distribution. Here’s how they address PBO’s challenges:

1. Minimal HAZ – Preserving Material Integrity

The highly concentrated energy acts within microseconds, vaporizing material instantly rather than allowing heat to diffuse. The result is a HAZ of only a few microns, maintaining PBO’ original strength and modulus.

2. Smooth Edges – Eliminating Fatigue Risks

The stable, focused beam produces smooth, burr-free cuts without bead formation. This reduces friction against guides, prevents stress concentration, and extends service life.

3. Non-Contact Processing – Avoiding Physical Damage

Laser cutting eliminates crushing or deformation caused by mechanical contact, ensuring consistency for high-value materials like PBO.

4. Intelligent Control – Enabling High-Volume Production

GW lasers integrate seamlessly with automation systems, enabling high-speed, precise cutting with excellent power stability. A dedicated process database for PBO ensures repeatable quality at scale.

Join Us in Empowering the Future of Humanoid Robotics

The humanoid robotics industry is a multidisciplinary race spanning materials, actuation, controls, and AI. As a key enabler for dexterous hands—the core actuators of robots—GW offers not only advanced laser hardware but also complete cutting solutions for high-performance fibers like PBO and UHMWPE. Our technical team is ready to collaborate with innovators across the field to refine processes and tackle manufacturing challenges.

From UHMWPE to PBO, the evolution of tendon materials reflects the pursuit of extreme performance in robotics. Advanced processing technology bridges the gap between lab-grade materials and mass production. GW’s high-brightness fiber lasers provide that bridge—ensuring every tendon is flawlessly crafted to equip humanoid robots with the most responsive and reliable “hands” for the age of smart manufacturing.

If you are exploring tendon selection, prototyping, or mass production for dexterous hands, contact us via our website or official social channels. GW LaserTech is committed to sharpening innovation with light—empowering your robotics journey with precision and reliability.

0

0