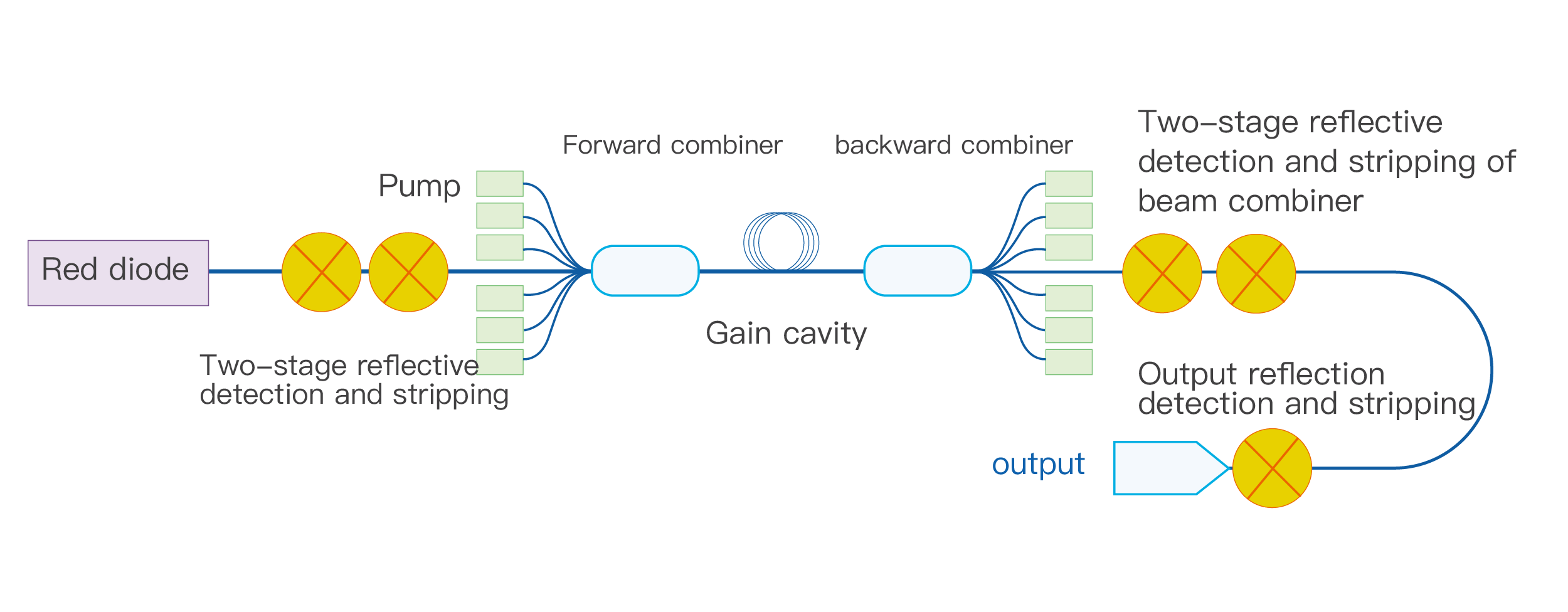

With 976nm high-efficiency bi-directional pumping technology as the core technology and the mission of "making laser a universal tool for all", GW Laser has successfully achieved the technological breakthrough from water-cooled 976nm to air-cooled 976nm through continuous R&D efforts since 2016, bringing a brand new direction of development for the laser industry. GW Laser has successfully achieved the technological breakthrough from water-cooled 976nm to air-cooled 976nm, bringing a new development direction for the laser industry. In the handheld welding market, GW Laser continues to deepen its product line, sticking to its roots in the water-cooled handheld welding market and providing various lasers required by the market, while in the air-cooled handheld welding market, GW Laser continues to lead the trend of the industry with its outstanding intelligent handheld laser welder, bringing a brand-new revolution in the welding experience for the users.

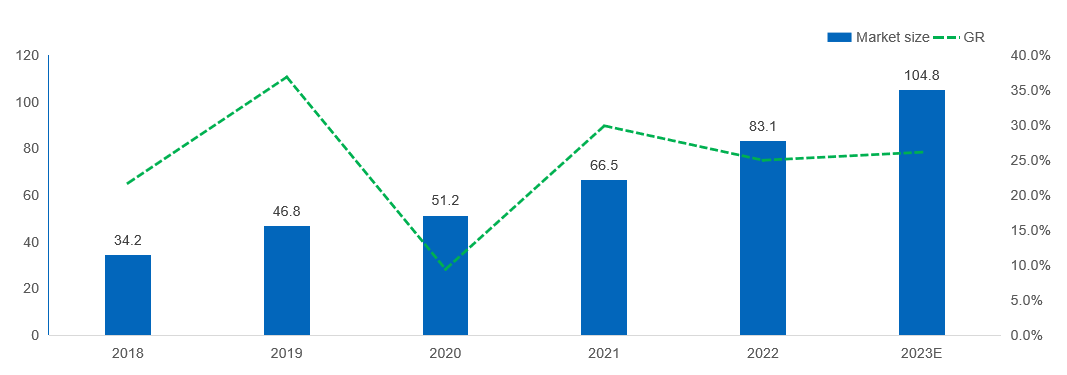

Vast Prospects, Prosperous Times for Welding Market

In the past six years, the emergence of laser welding equipment for users to bring

unprecedented flexibility, precision and efficiency. 2023 China's laser welding equipment

market size will exceed 10 billion yuan, is expected to 2025, the laser welding equipment

industry market size will be more than 30 billion, the laser welding market has come to

the "explosion! The laser welding market has come to the "explosion" of the key point.

China Laser Welding Equipment Market Sales and Forecasts

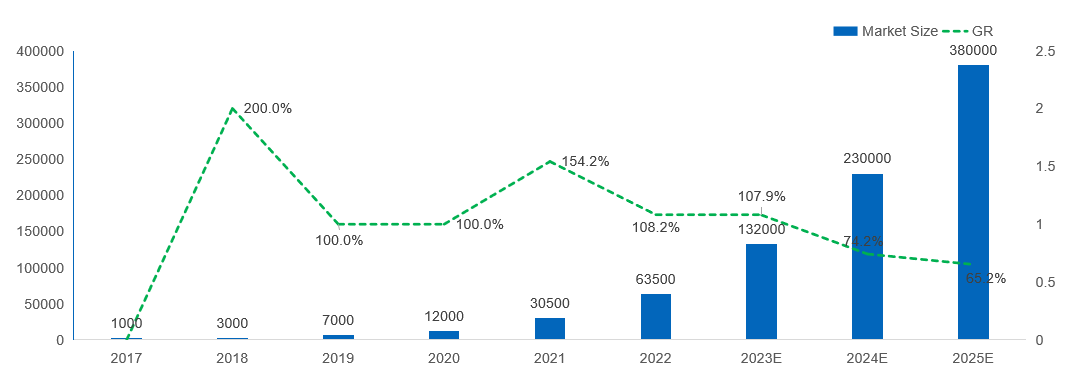

Handheld laser welding machine is more favoured by the market because of the characteristics of "portability, high efficiency, high precision and multi-functional application". Since 2017, the handheld laser welding machine for six consecutive years of year-on-year growth of more than 100%; is expected to 2025 China's laser handheld welding sales of about 380,000 units.

Handheld Laser Welder Market Size Forecast 2017-2025E

Thin, light and strong, made for welding

GW Laser launched the YLLS-D40-1200-W, designed for welding applications, with a new appearance design, integrated aluminium heat sink module, heat generating components are placed on both sides of the heat sink, which can effectively increase the efficiency of heat dissipation.The weight of the YLLS-D40-1200-W is less than 18kg and the volume is less than 0.01m³, which brings a new lightweight solution for the welding field. solution. Adopting water-cooled heat dissipation, it supports matching with water-cooled cabinets commonly used in the market, and it can carry out continuous welding work for a long time to ensure the long time batch manufacturing work of laser welding.

Continuous and pulsed working modes optimize the processing quality, easy control interface, and the small core diameter of the output fibre (M2≤1.4) has high beam quality. Meanwhile, GWYLLS-D40-1200-W also adopts ABR super anti-high-reflection technology, which can easily weld common steel (such as carbon steel, stainless steel, galvanised steel, etc.), as well as aluminium alloy, brass and other high-reflection materials.

The peak of lightweight, forced air-cooled handheld welding machine is leading the way

The new forced air-cooled handheld welding machine covers 500W, 800W and 1200W power range, adopts 3D phase change cooling technology, which can intelligently change the speed of the fan according to the temperature of the air-cooled board, and also matches with the high-temperature-resistant chip technology programme to meet most of the daily operating environments of the customers. New internal structure design, wire feeder control board is integrated by the motherboard, which greatly improves the user experience. From the perspective of customer use and practical application scenarios, the volume of the handheld welding machine <0.05m³, a very small footprint, within the welding operation, can be conveniently moved.

GW Laser forced air-cooled handheld welding machine is equipped with 7-inch high-definition touch screen, equipped with SMAT intelligent operating system independently developed by GW Laser, can be connected to the Internet through the network or WIFi, through APP and WEB to achieve remote monitoring and data collection, including real-time monitoring of the product's status, operating parameters, data uploaded to the cloud, and fault warning, thus reducing the failure rate of the equipment to improve equipment stability, while customers can be online to enhance the stability of equipment, and at the same time, customers can be online. equipment stability, at the same time, customers can online feedback equipment questions, simple problems remote online solution.

Welding upgrade, air-cooled intelligent laser handheld welding machine

GW laser active air-conditioning direct cooling intelligent laser handheld welding machine with active air-conditioning direct cooling technology, can be in -20 ~ 50 ℃ full power stable operation for 24 hours, when the operating environment temperature is too high or too low, the intelligent temperature control system will control the flow of the refrigerant, so as to achieve the effect of refrigeration or heating, in order to achieve the operating temperature inside the laser in the most suitable for the laser operating environment, to your laser! Adding an "air conditioner" ensures stable operation of the laser without the need to worry about the operating environment.

For users with different operating environments and operating scenarios, an easy-to-move laser handheld welding machine is crucial. Bright Laser's active air-conditioned, direct-cooled, intelligent handheld laser welding machine weighs ≤62kg and has a volume of about 0.1m³, which perfectly meets the needs of users who need to move around with a small workbench, and who can easily change the place of operation.

At the same time, the self-developed handheld welding torch, ergonomically designed, weighs only 580g, and the welding process is not tiring. Small core diameter optical cable design, the same power section welding capacity is stronger, deeper melting depth, better welding effect, weld seam beautiful, no deformation, no deformation of the weldment, no need for follow-up treatment.

Power | Materials | Stainless steel | Carbon steel | Aluminum | Brass | Red copper |

1500W 25um | Single-side penetration | 4.5mm | 4.5mm | 4mm | 4mm | 2mm |

Double penetration | 9mm | 9mm | 8mm | 8mm | 4mm |

Power | Materials | Stainless steel | Carbon steel | Aluminum | Brass | Red copper |

2000W 25um | Single-side penetration | 6mm | 6mm | 6mm | 5mm | 2.5mm |

Double penetration | 12mm | 12mm | 12mm | 10mm | 5mm |

In the water-cooled handheld welding market, GW Laser has always been at the forefront of technology and is committed to providing users with superior laser solutions. We understand the needs of the market and strive to meet the expectations of our customers by continuously optimising product performance and improving stability and reliability. At the same time, GW Laser will continue to lead the industry by actively investing in research and development to introduce the development of air-cooled technology and more innovative products.

We are grateful to every customer who supports us and look forward to witnessing the bright future of the laser industry together with you.

0

0